Ask our team. We're ready to help!

As food & beverage processors drive toward higher productivity and expanded product offerings, food safety remains critical to success — and can impact the entire organization.

Bakery manufacturers know that controlling dough temperature in the mixer is one of the principal challenges in bakery operations.

High-efficiency cryogenic chilling processes boost productivity and streamline food processing operations while reducing costs. At the same time, they help maintain proper food temperatures throughout plants, which is essential for food quality, preservation and food safety. Download this whitepaper for an introduction to food processing utilizing cryogenic food-grade gases – either carbon dioxide (CO2) or nitrogen (N2).

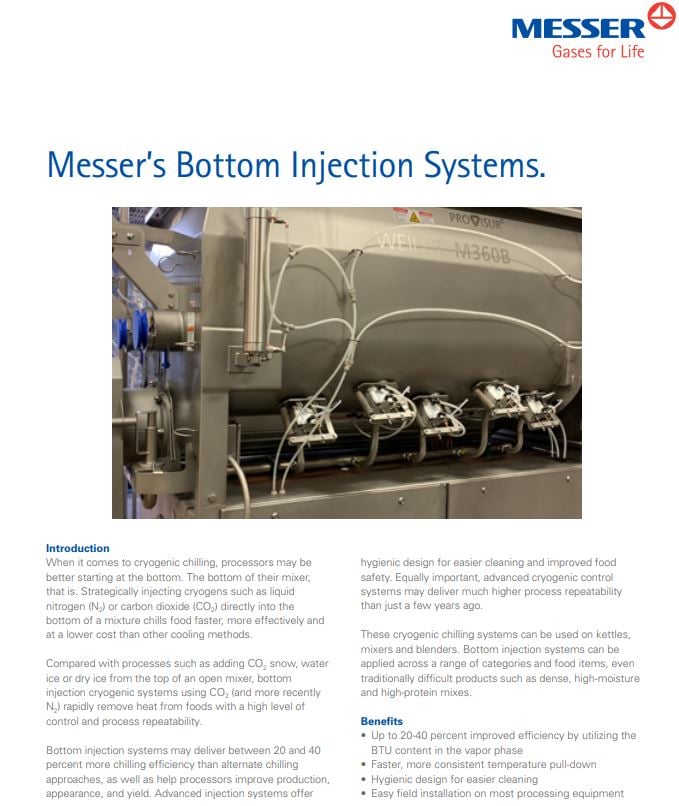

When it comes to cryogenic chilling, processors may be better starting at the bottom. The bottom of their mixer, that is. Strategically injecting cryogens such as liquid nitrogen (N2) or carbon dioxide (CO2) directly into the bottom of a mixture chills food faster, more effectively and at a lower cost than other cooling methods.

Are you challenged by increasing input costs, inconsistent quality, or reduced output? Protein processors have valuable options for identifying and solving the root causes of a number of common yield problems.

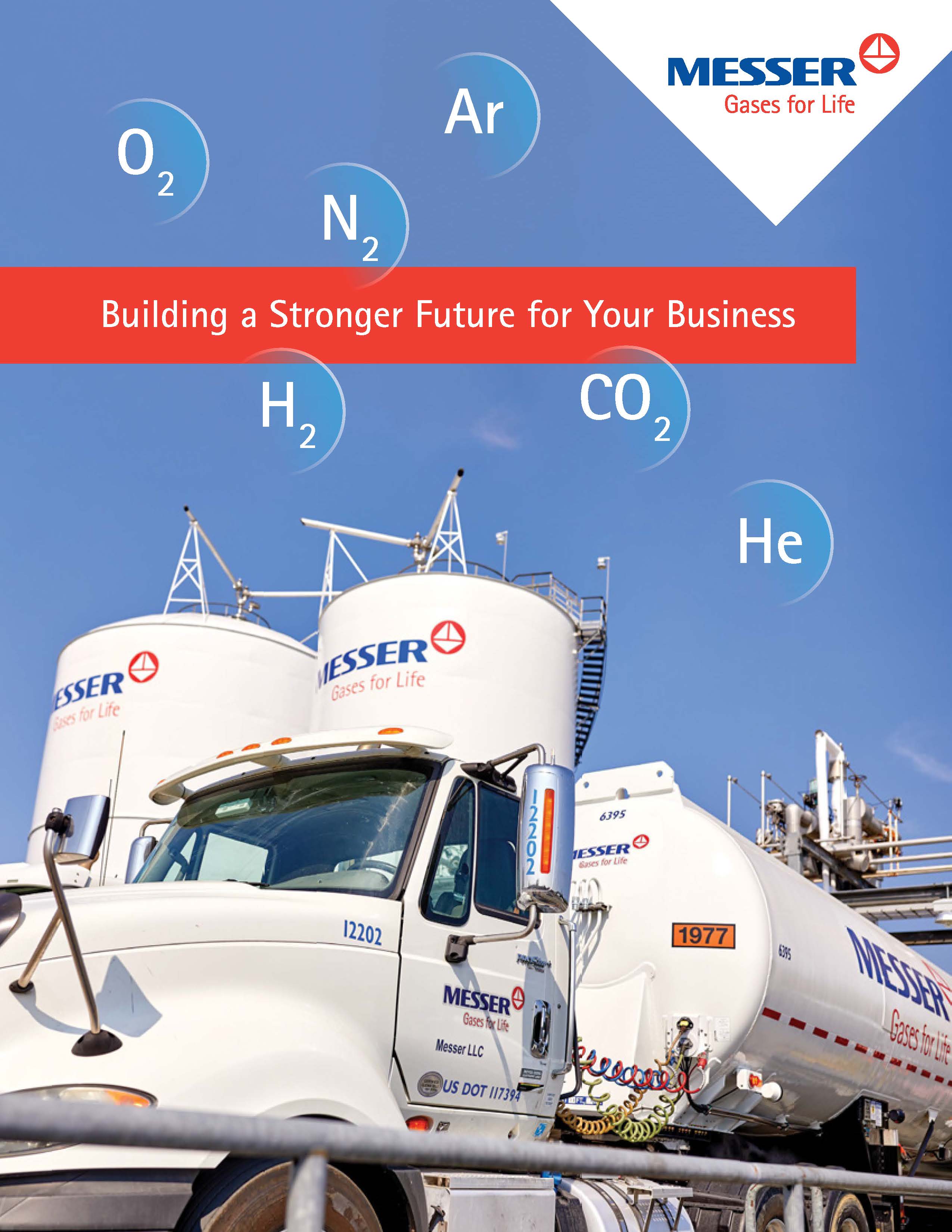

If your business depends on industrial gases, you need a dependable supplier of quality products. You also need a leader in industrial gas technologies, committed to delivering solutions that create value in areas of productivity, quality and reduced operating costs that allow you to maintain focus on your core business. This is where Messer excels, and these pillars form the cornerstone of our success.

Welcome to the epicenter of innovation and customer solutions in applied gas technologies - the Messer Technical Center in Cleveland, Ohio. Here, our team of Messer engineers demonstrate leading application technologies to customers and innovate to address emerging industry needs.

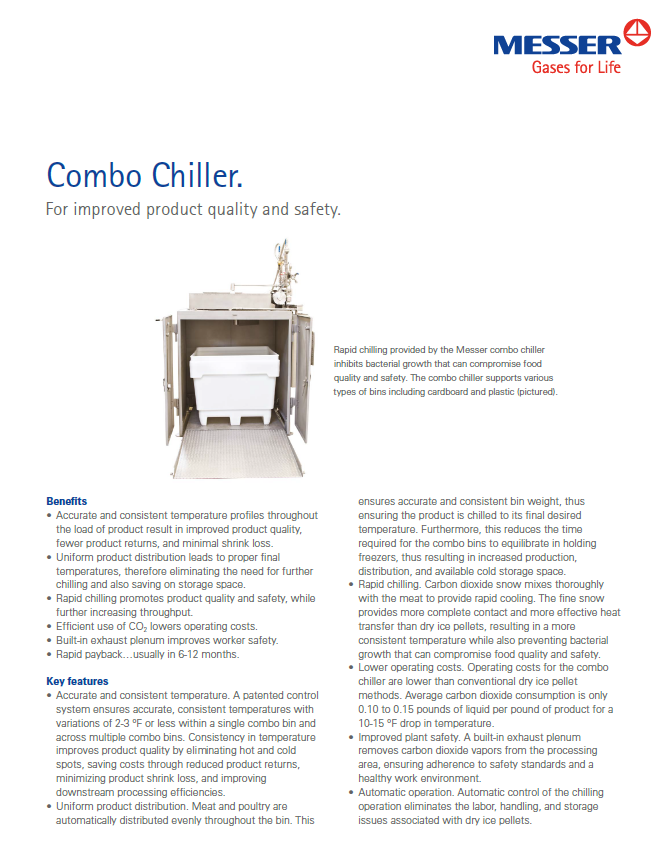

Rapid chilling provided by Messer's Combo Chiller inhibits bacterial growth that can compromise food quality and safety. The Combo Chiller supports various types of bins including cardboard and plastic.

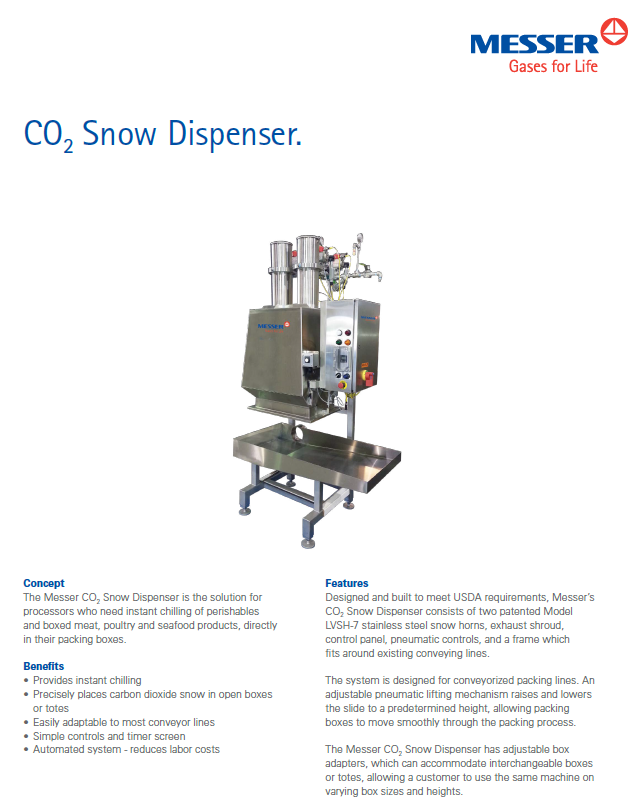

Messer's Snow Dispenser is the solution for processors who need instant chilling of perishables and boxed meat, poultry and seafood products, directly in their packing boxes.

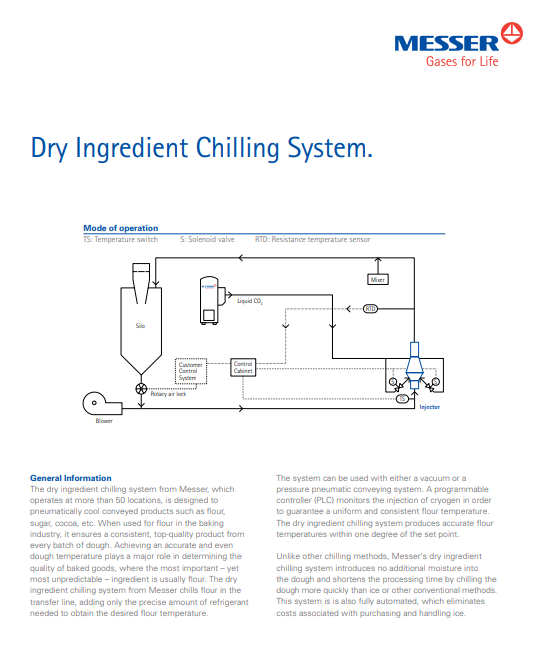

The dry ingredient chilling system from Messer is designed to pneumatically cool conveyed products such as flour, sugar, cocoa, etc. When used for flour in the baking industry, it produces a consistent, top-quality product from every batch of dough.

The KRYOJECTOR® bottom injector from Messer is a patented cryogenic bottom injection system working with either liquid nitrogen or liquid carbon dioxide. Wherever fast and efficient chilling without additional process equipment is needed, the KRYOJECTOR injector is the answer.

Messer's Modified Atmosphere Packaging (MAP) is suited for the production and packaging of rye bread, sweet bakery products, and pies. It eliminates the risk of excess carbon dioxide – the cause of ‘ice melt’ – and offers the ability to balance the concentration with nitrogen.

Messer‘s Modified Atmosphere Packaging brings you a full range of tailored solutions to meet the packaging requirements for meat and poultry.

Utilizing Modified Atmosphere Packaging (MAP) and the right gas mixture can extend the shelf life by at least a few days and possibly up to two weeks in raw packaged

fish such as cod, flounder, plaice, haddock, and whiting compared to packaging in traditional atmospheres similar to that of air.

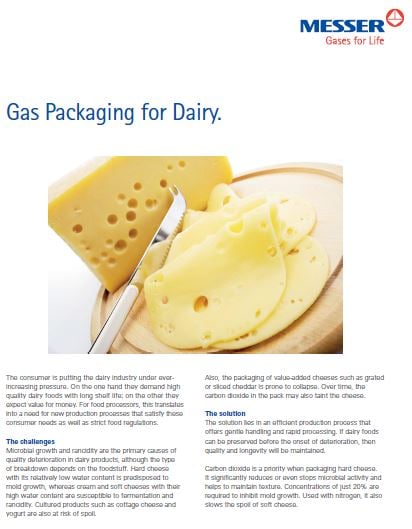

The consumer is putting the dairy industry under ever-increasing pressure. On the one hand, they demand high-quality dairy foods with long shelf life; on the other, they

expect value for money. For food processors, the solution is an efficient production process that offers gentle handling and rapid processing.

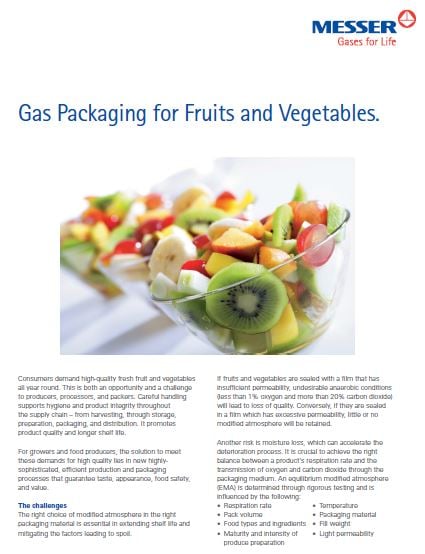

Consumers demand high-quality fresh fruit and vegetables all year round. Careful handling supports hygiene and product integrity throughout the supply chain. For growers and food producers, the solution to meet these demands lies in highly sophisticated, efficient production and packaging processes that preserve taste, appearance, food safety, and value.

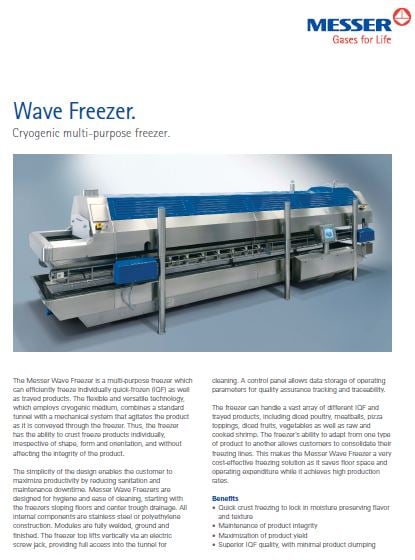

The Messer Wave Freezer is a multi-purpose freezer which can efficiently freeze individually quick-frozen (IQF) as well as trayed products. The flexible and versatile technology, which employs cryogenic medium, combines a standard tunnel with a mechanical system that agitates the product as it is conveyed through the freezer.

Strategically injecting cryogens such as liquid nitrogen (N2) or carbon dioxide (CO2) directly into the bottom of a mixture chills food faster, more effectively and at a lower cost than other cooling methods. Bottom injection systems may deliver between 20 and 40 percent more chilling efficiency than alternate chilling approaches, as well as help processors improve production, appearance, and yield.

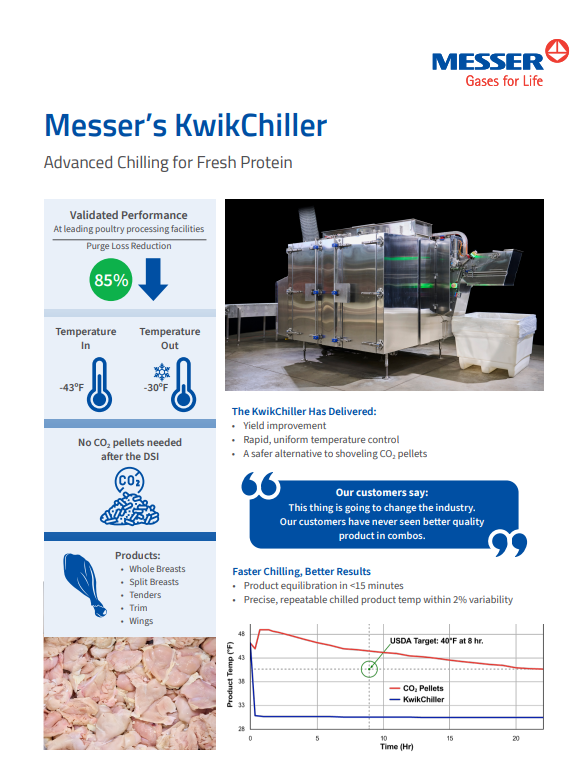

The new KwikChiller delivers high-capacity chilling when floor space is at a premium. Developed in collaboration with poultry processors, successful installations demonstrated significant yield improvements and rapid, uniform temperature control. The nitrogen powered KwikChiller features an integrated exhaust, a safer alternative to shoveling CO2 pellets and fits through a standard dock door for easy installation.

“The Messer Food team worked closely with my management on implementation, often after hours to minimize downtime, right down to training all our employees on the new technology."

See four real-life examples of how protein processors are leveraging new techniques to achieve tangible gains in production throughput, efficiency, cost and product quality in a variety of product categories, including pork, chicken, beef, meat alternatives, and IQF products.

“Normal” may never be the same for food processors. The health of employees, how to engage them and their general welfare – on top of food safety, sanitation and hygiene practices – have been brought to the forefront because of COVID-19. Download this new checklist to learn how you can take specific measures to meet employee concerns, enhanced quality protocols and consumer demand through times of uncertainty.

A reliable cryogenic freezer is a critical part of any food plant. An existing freezer that lacks quality parts or malfunctions can lead to frequent shutdowns, higher maintenance and unnecessary costs. Download this checklist to potentially prevent future failures of your freezing technology, evaluate current options and choose the right fit for your plant.

Food production is a multi-faceted operation, extending beyond preparation and cooking to overall plant operations, business practices and the supply chain. In addition, the COVID-19 pandemic has produced its own challenges. With producers striving to maximize food product quality and production rates, food processing efficiency continues to be critical to driving profitability. Download this checklist for 5 actionable strategies to help elevate the manufacturing efficiency of your plant.

Reduce food waste on processing lines and deliver more product to customers by optimizing operations, prioritizing employee training, creating and maintaining automated processes, and upgrading to advanced tools such as ERP software and cryogenic freezing and chilling solutions to preserve food longer.

%20(1).png)

Why do so many food manufacturers struggle with yield? Explore the issues surrounding food processing yield, the common difficulties manufacturers face, and the innovative solutions designed to address these issues and increase operational efficiency.

For protein processors in a highly competitive industry where product quality and food safety standards need to be carefully managed through every step of the production process, this checklist provides five practical steps for success.