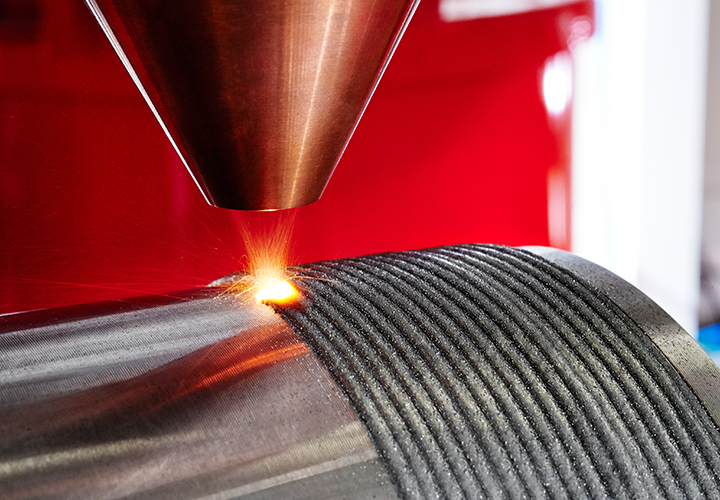

Additive manufacturing processes continue to redefine the concept of what’s possible on the manufacturing floor, enabling low-cost, on-demand flexibility and customization unheard of just a few years ago. However, if you want the best results, you need to start with the best source materials—which means gases from Messer are a must-have.

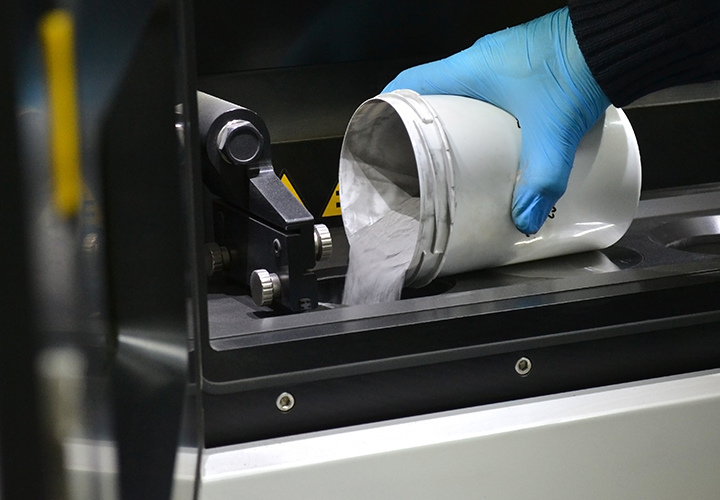

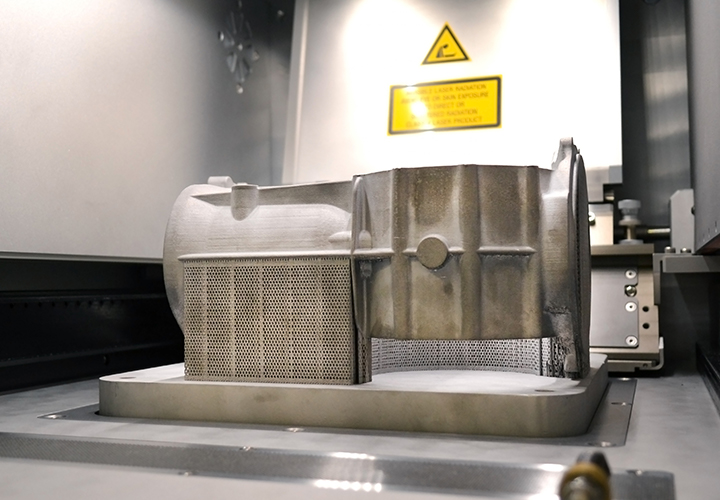

Messer offers technology solutions and experience to cover the whole AM pipeline, from the production of metal powder through post-processing HIP and surface treatment, and everything in between. Not only do we offer a market-leading selection of meticulously designed gases and supply options, we put highly engaged customer support at your disposal. No matter how ambitious your idea is, we are here to help you take it from dream concept to tangible reality.

Whether you manufacture for the aerospace industry, energy, automotive industry, medical field, or another market altogether, Messer will work with you every step of the way, researching and developing new techniques and creating cutting-edge solutions customized to your needs.