When it comes to gas-enabled applications such as cryogenics, Messer engineers are among the most knowledgeable in the industry. If you need a devoted company to help you meet your quality, safety and efficiency targets, Messer is the only name you need to know.

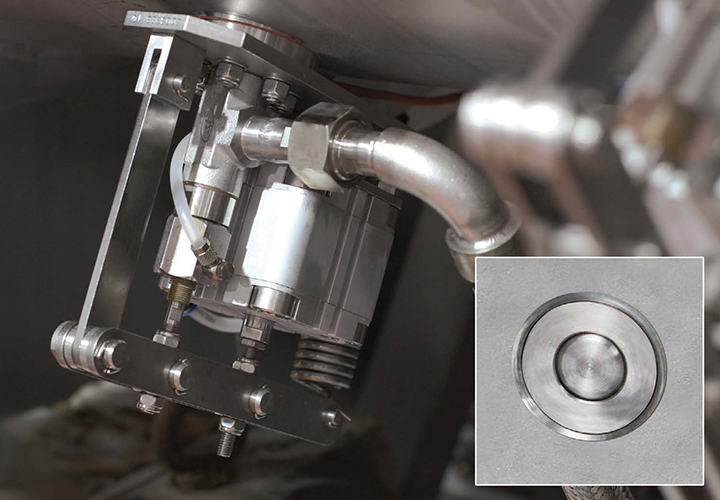

We’ve spent decades devising unique cutting-edge solutions that enable our customers to enhance quality, boost repeatability, and improve throughput with a portfolio of hygienically designed, state-of-the-art chilling systems.

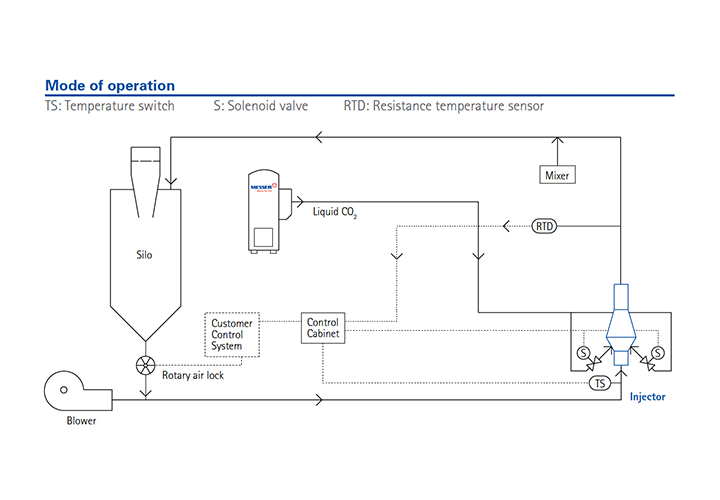

Traditional ice-based chilling is labor-intensive and increases the likelihood of production bottlenecks and workplace injuries. Mechanical chilling requires ammonia-based refrigerants, which are hazardous chemicals. But cryogenic systems from Messer utilize naturally occurring inert gases for a safer, smoother, solution.

Best of all, Messer offers flexible equipment rental and purchase agreements and provides our customized turnkey service. Which solution can we implement for you?