As a global leader in cryogenic freezing technologies for the food industry, including spiral and tunnel freezers, Messer has decades of experience providing innovative solutions to our customers’ needs. We are uniquely qualified to meet the changing demands of the food processing sector. If you have a freezing or chilling challenge – we can help!

Messer engineers have helped our customers grow and improve the safety and efficiency of their processes resulting in millions of dollars to their bottom line.

Need an experienced supplier of food grade carbon dioxide (CO2) and nitrogen (N2) gases for your freezing and chilling needs? We are that supplier. Could you use informed advice and guidance? Our food industry engineers are eager to help you improve product yield, boost quality, and improve both throughput and ROI.

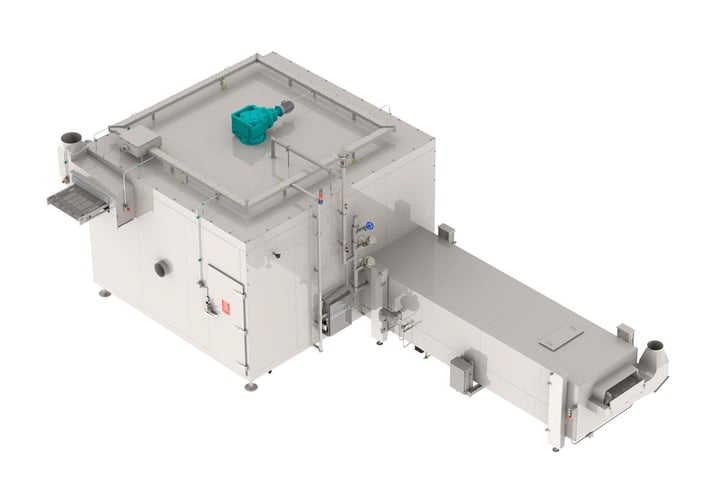

Finally, if you’re ready to upgrade to state-of-the-art cryogenic freezers, including spiral and tunnel freezers, we are the process engineers you know and trust.

Our tunnel and spiral freezer designs redefine the cutting edge, and we offer a complete range of cryogenic freezers for efficient in-line forming and freezing. Better yet, our flexible leasing arrangements make it easy for you to adopt the latest technology with a minimum of capital outlay.