Ask our team. We're here to help!

eNOx™ High-performance NOx Removal Technology

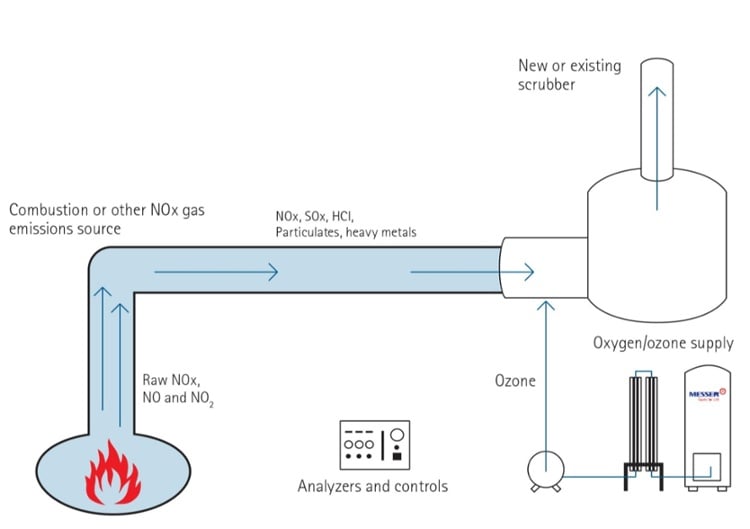

Messer is proud to offer eNOx NOx abatement technology, a low-temperature, ammonia-free, end-of-pipe retrofit that reliably and stably removes 95+% of NOx regardless of load, concentration, particulates or the presence of SOx. Messer also offers the solution as a polishing step in your process. It can work downstream of your existing NOx abatement technology and reduces your operating costs.

How does eNOx™ work?

Combustion creates NOx. eNOx treats NOx with a stream of ozone that reacts to become N2O5. A dry or aqueous scrubber then converts N2O5 to nitric acid (HNO3), minimizing your emissions and leaving you with a salt or solution.