Ask our team. We're ready to help!

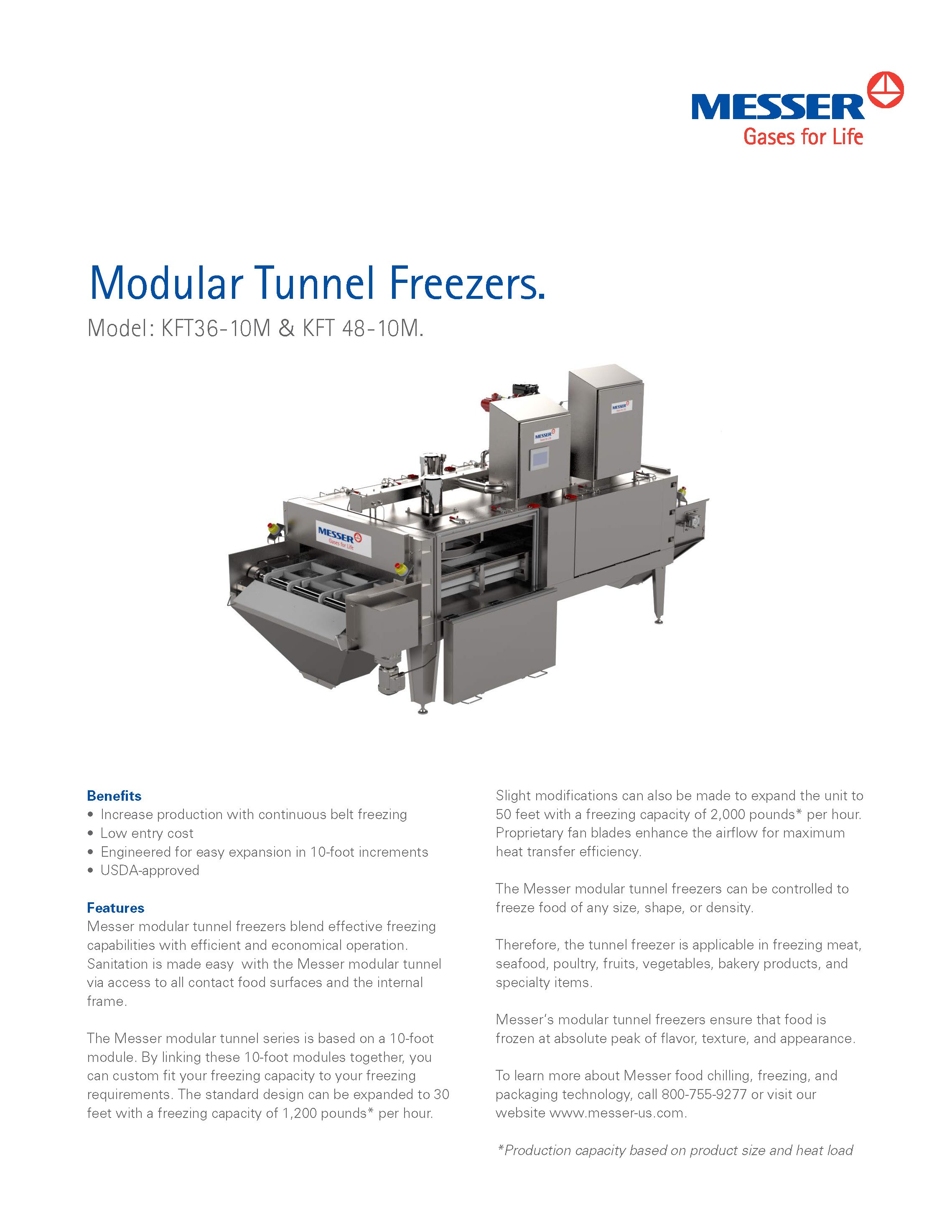

Blends effective freezing capabilities with efficient and economical operation at an unbeatable price.

Messer’s patented impingement technology combines cryogenic gases with high-velocity convective airflow to achieve rapid chilling and freezing of food products.

As a leading provider of bulk medical gas supply and systems, Messer has developed Hospital Services to design and implement these critical life support systems.

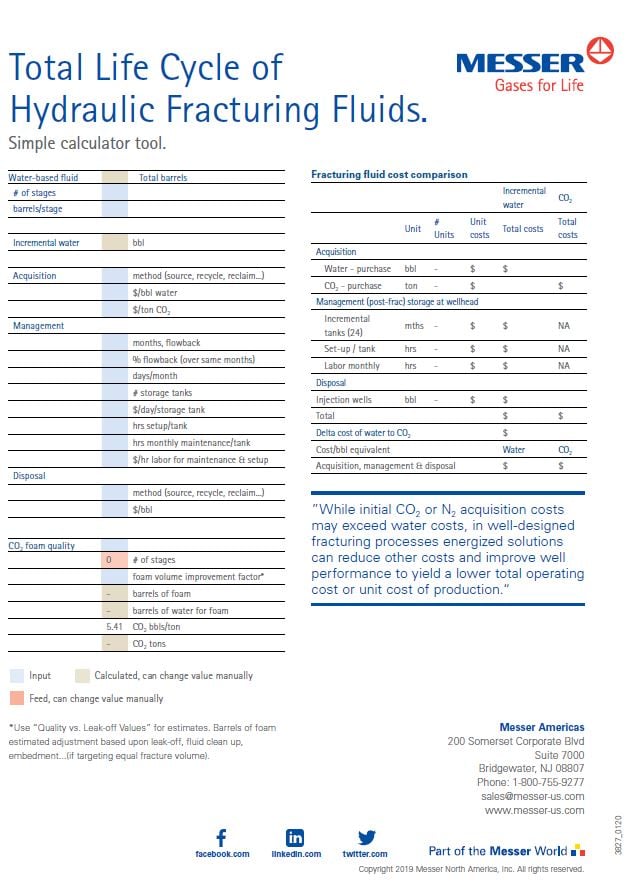

A simple calculator tool.

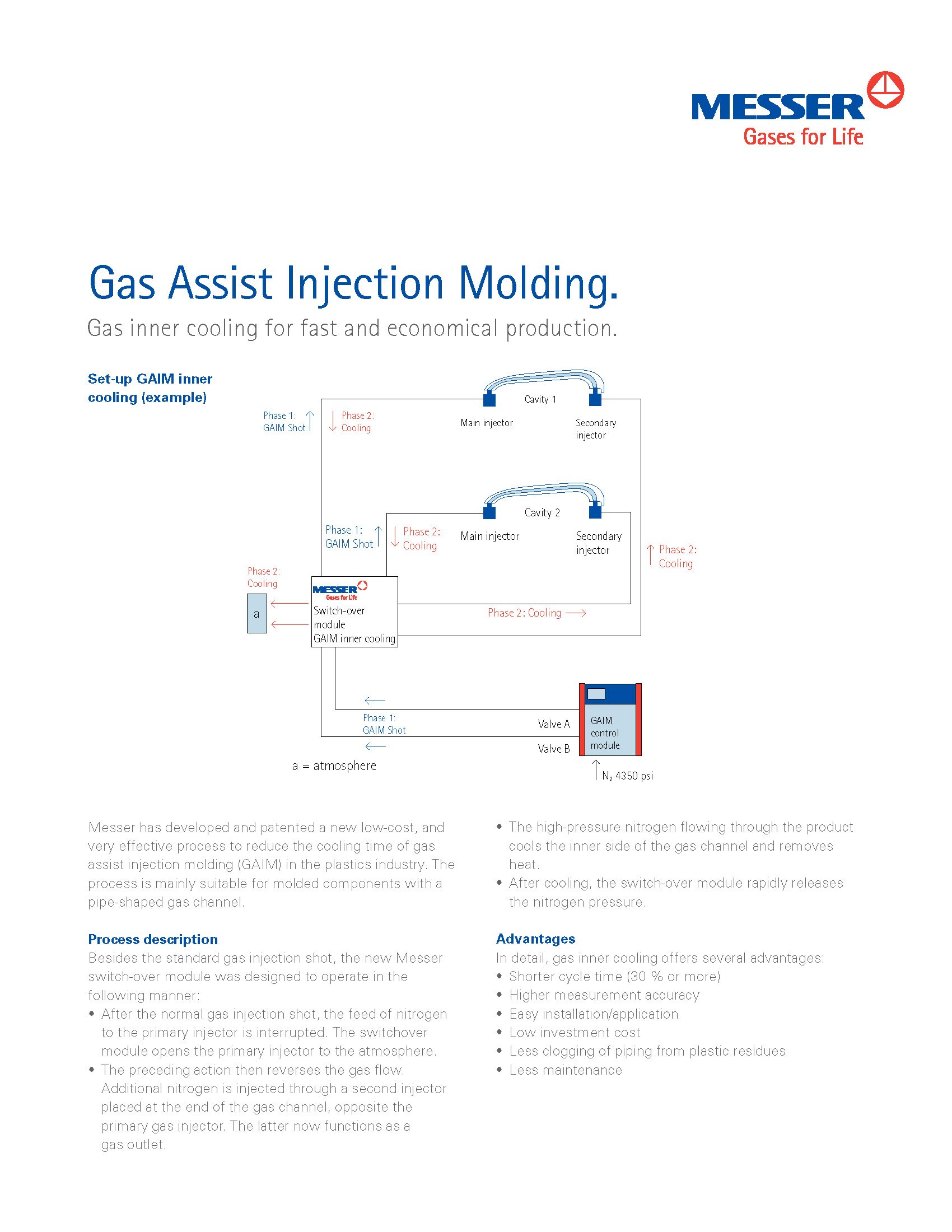

Gas inner cooling for fast and economical production.

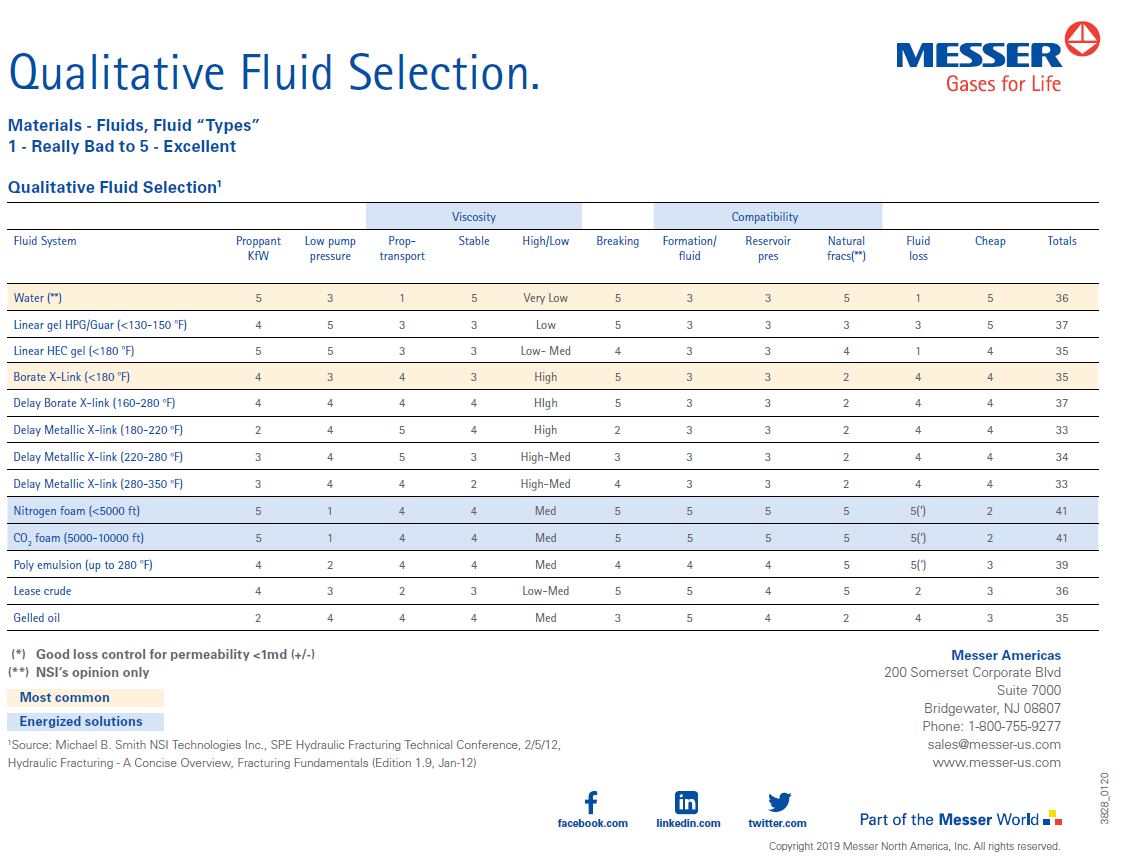

This datasheet provides the ranking of fracturing fluids based on 11 key characteristics, and why CO₂ and N₂ may be the preferred choice.

Uniform heating for higher productivity, no hot spots and less emissions.

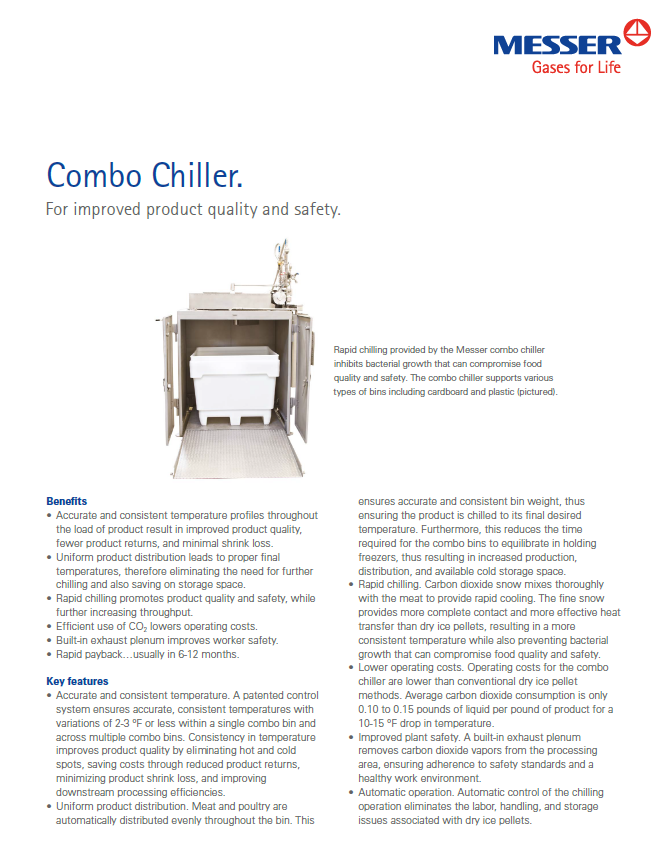

Rapid chilling provided by Messer's Combo Chiller inhibits bacterial growth that can compromise food quality and safety. The Combo Chiller supports various types of bins including cardboard and plastic.

Messer's Snow Dispenser is the solution for processors who need instant chilling of perishables and boxed meat, poultry and seafood products, directly in their packing boxes.

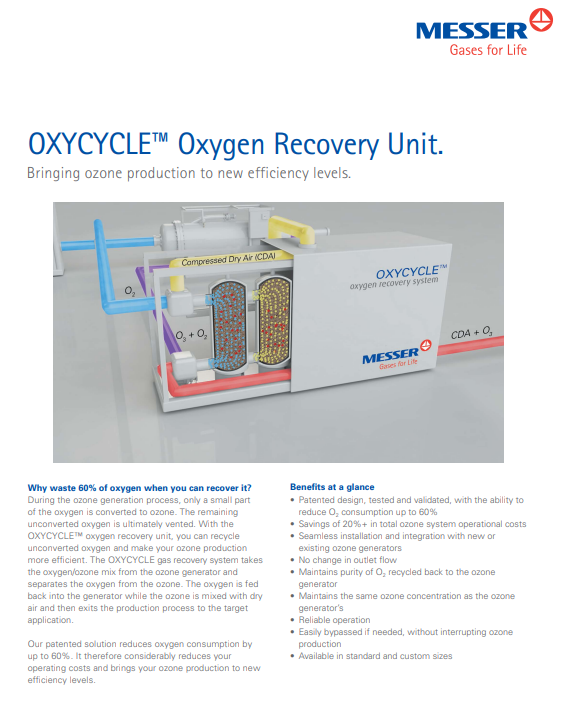

Messer's patented OXYCYLE oxygen recovery unit reduces oxygen consumption by up to 60%, reducing operating costs and bringing ozone production to new efficiency levels.

In order to comply with regulations, one customer was looking for an environmentally-friendly way of SWS gas treatment.

Oxygen enrichment for intensification of Claus processing.

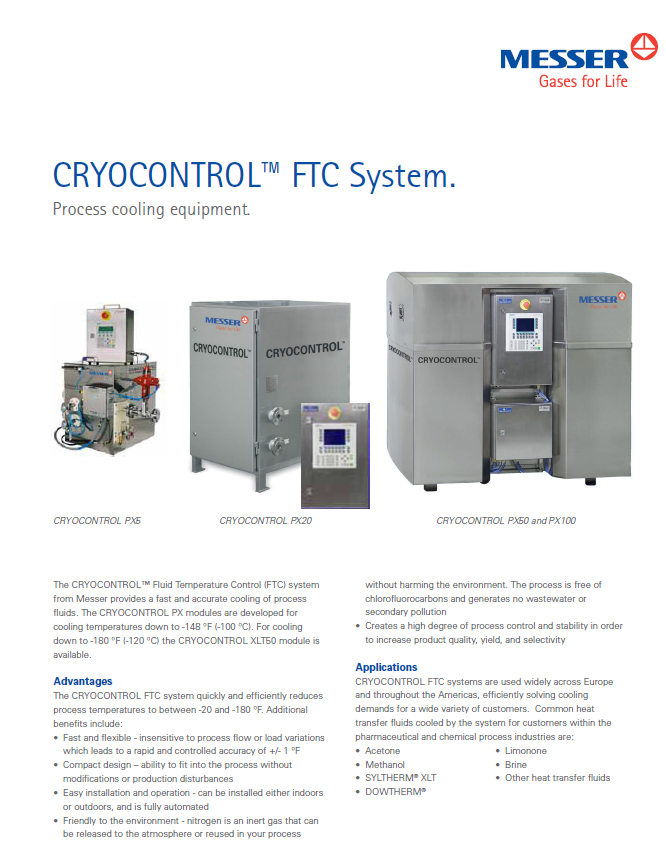

The CRYOCONTROL™ Fluid Temperature Control (FTC) system from Messer provides a fast and accurate cooling of process fluids.

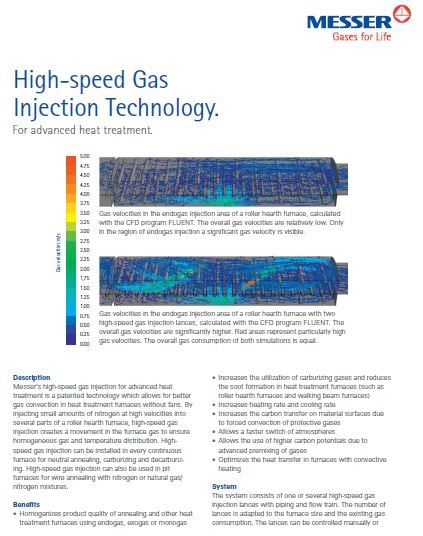

Messer’s high-speed gas injection for advanced heat treatment is a patented technology which allows for better gas convection in heat treatment furnaces without fans.

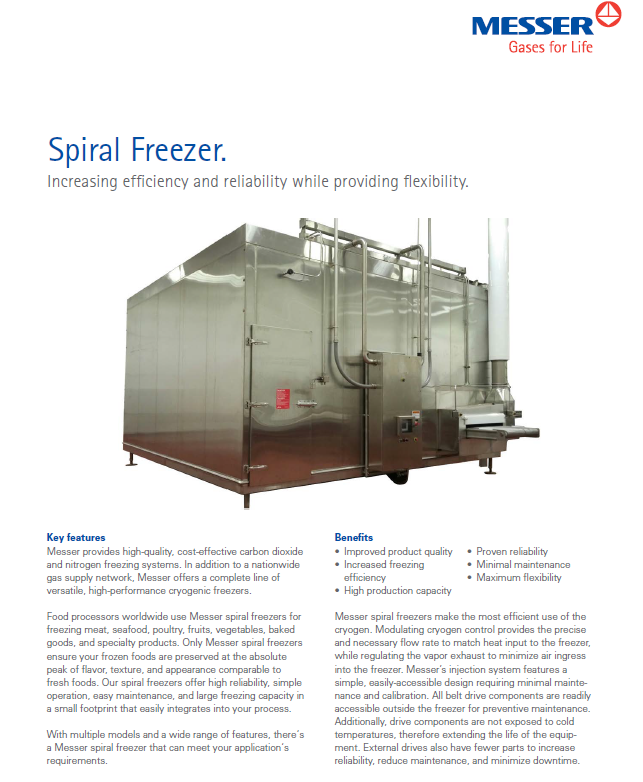

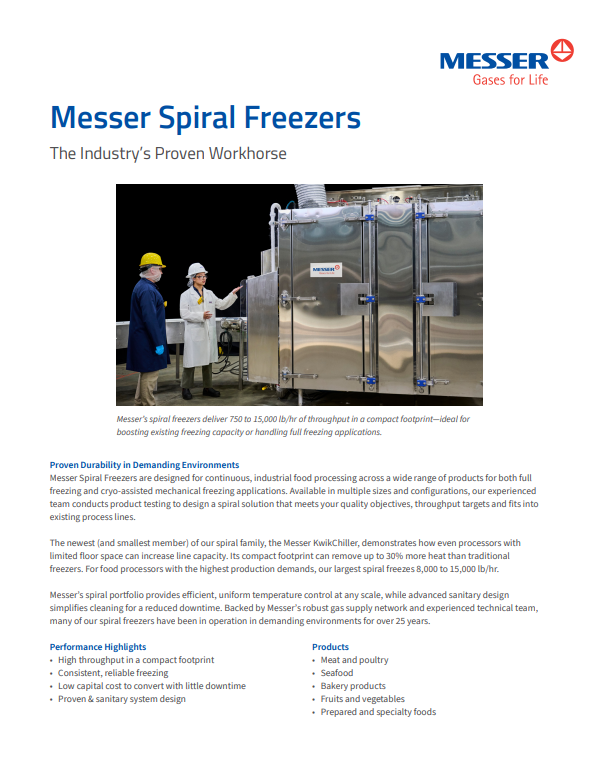

Food processors worldwide use Messer spiral freezers for freezing meat, seafood, poultry, fruits, vegetables, baked goods, and specialty products.

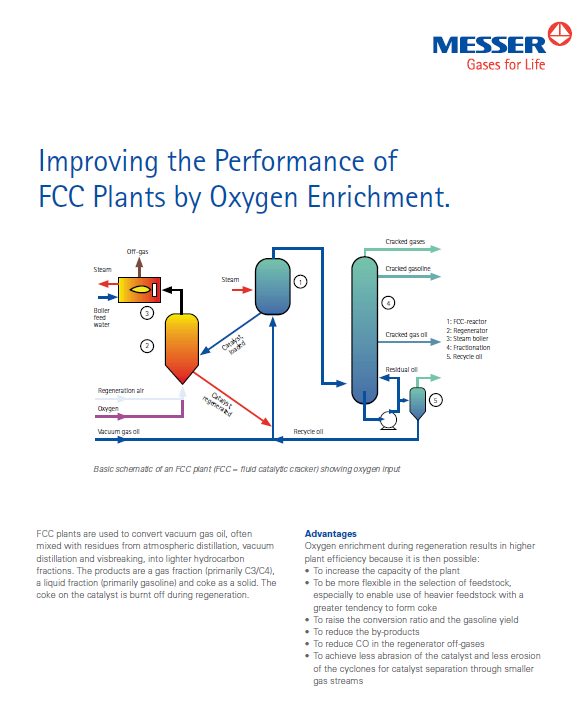

Messer's services for oxygen enrichment in FCC plants provide significant advantages, including higher plant efficiency.

The NEUTRA water treatment method and installations employ carbon dioxide in order to neutralize alkaline waters. When dissolved in water, carbon dioxide forms carbonic acid and reduces the pH value to the appropriate level.

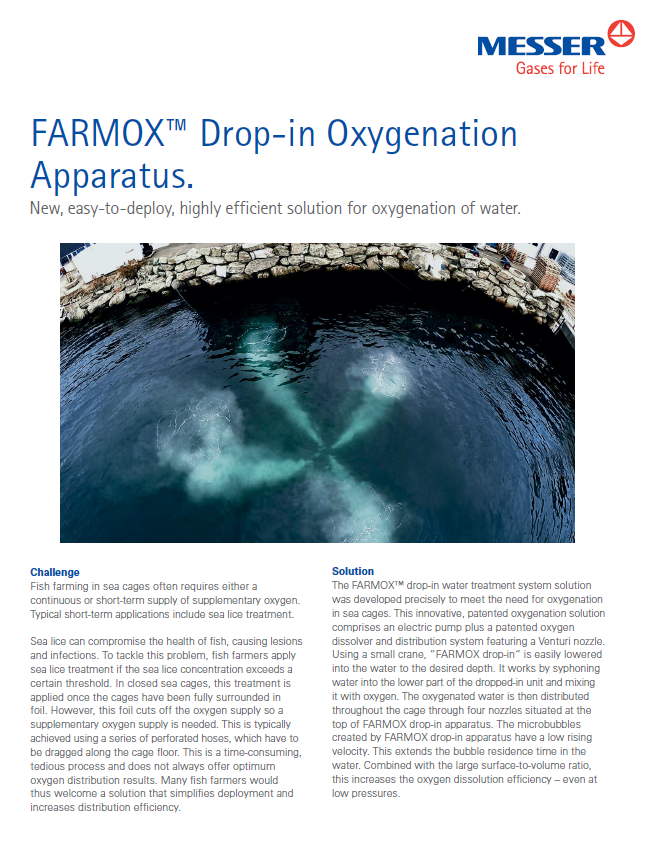

The FARMOX low pressure sidestream injection system is a low-pressure oxygenation system for seawater, brackish water, and fresh water tanks. The system is a patented all-in-one product which oxygenates and evenly distributes the water in the fish tank using an adjustable flow regime.

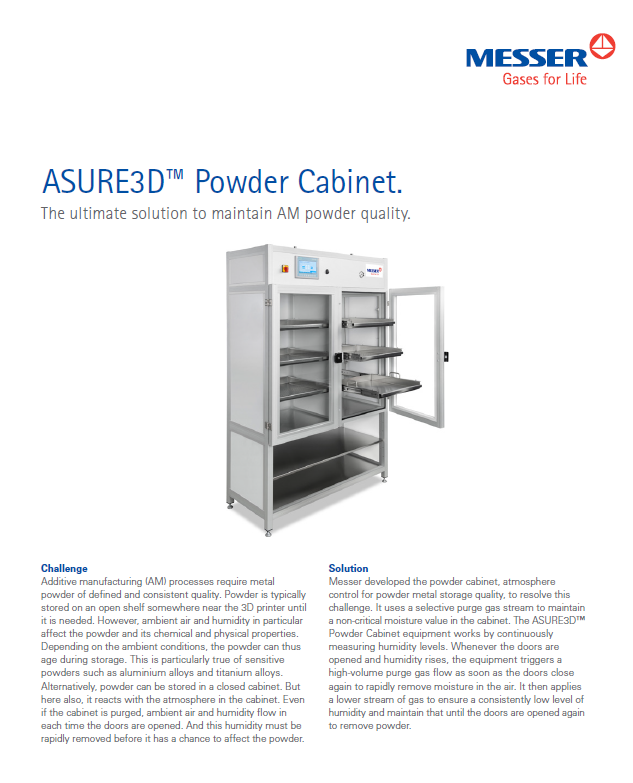

The ASURE3D Powder Cabinet equipment is valuable for cabinets with multiple storage shelves as these are a great place for ambient air and moisture to hide and constantly affect the powder particles. The equipment uses a highly directional gas stream and a carefully selected flow rate to reach the desired moisture value.

The FARMOX™ drop-in water treatment system solution was developed to meet the need for oxygenation in sea cages.

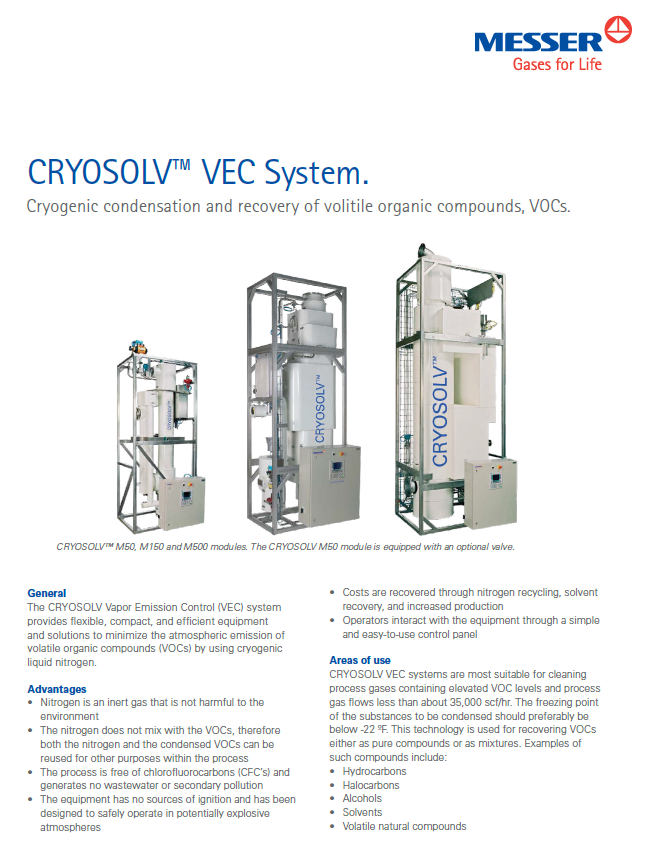

The CRYOSOLV Vapor Emission Control (VEC) system provides flexible, compact, and efficient equipment and solutions to minimize the atmospheric emission of volatile organic compounds (VOCs) by using cryogenic liquid nitrogen.

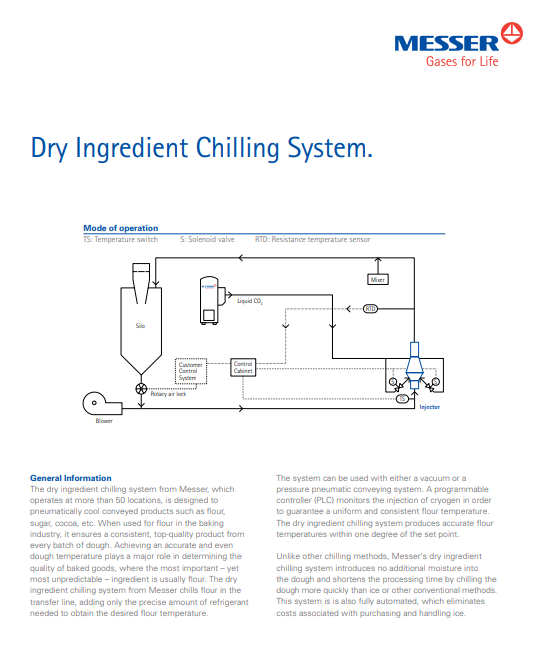

The dry ingredient chilling system from Messer is designed to pneumatically cool conveyed products such as flour, sugar, cocoa, etc. When used for flour in the baking industry, it produces a consistent, top-quality product from every batch of dough.

The KRYOJECTOR® bottom injector from Messer is a patented cryogenic bottom injection system working with either liquid nitrogen or liquid carbon dioxide. Wherever fast and efficient chilling without additional process equipment is needed, the KRYOJECTOR injector is the answer.

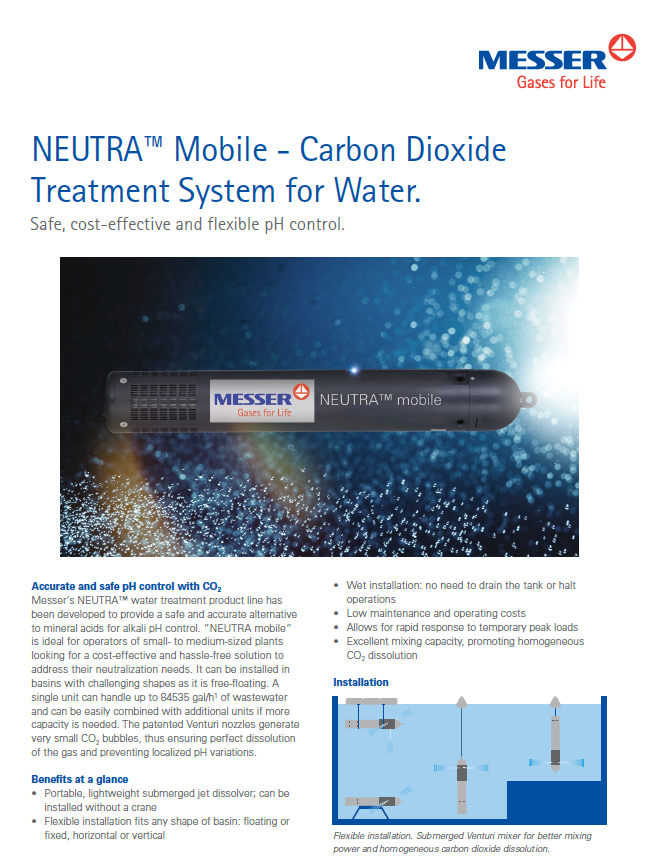

Messer‘s NEUTRA™ water treatment product line has been developed to provide a safe and accurate alternative to mineral acids for alkali pH control. “NEUTRA mobile“ is ideal for operators of small- to medium-sized plants looking for a cost-effective and hassle-free solution to address their neutralization needs.

Messer’s BIOX™ water treatment product line has been developed to meet aeration and mixing needs in wastewater treatment plants. The “BIOX mobile” is a flexible solution suitable for all industrial wastewater treatment plants using aeration processes.

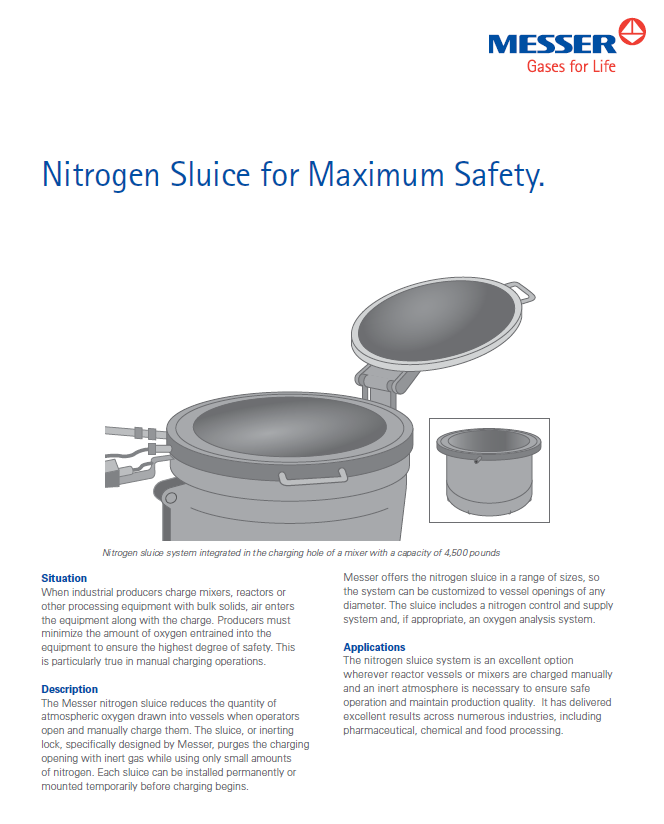

The Messer nitrogen sluice system is an excellent option wherever reactor vessels or mixers are charged manually and an inert atmosphere is necessary for safe operation and to maintain production quality. It has delivered excellent results across numerous industries, including pharmaceutical, chemical and food processing.

Messer's Modified Atmosphere Packaging (MAP) is suited for the production and packaging of rye bread, sweet bakery products, and pies. It eliminates the risk of excess carbon dioxide – the cause of ‘ice melt’ – and offers the ability to balance the concentration with nitrogen.

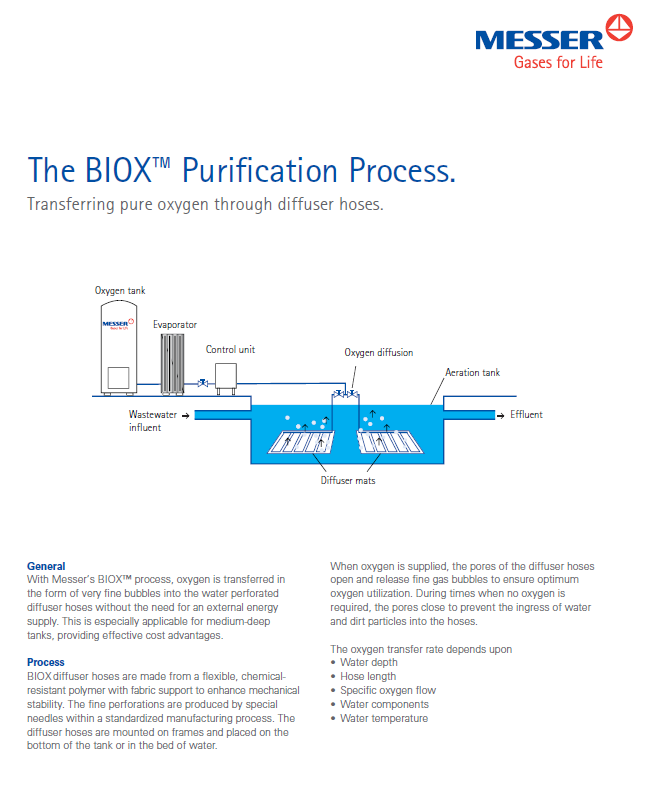

With Messer‘s BIOX™ process, oxygen is transferred in the form of very fine bubbles into the water perforated diffuser hoses without the need for an external energy supply. This is especially applicable for medium-deep tanks, providing effective cost advantages.

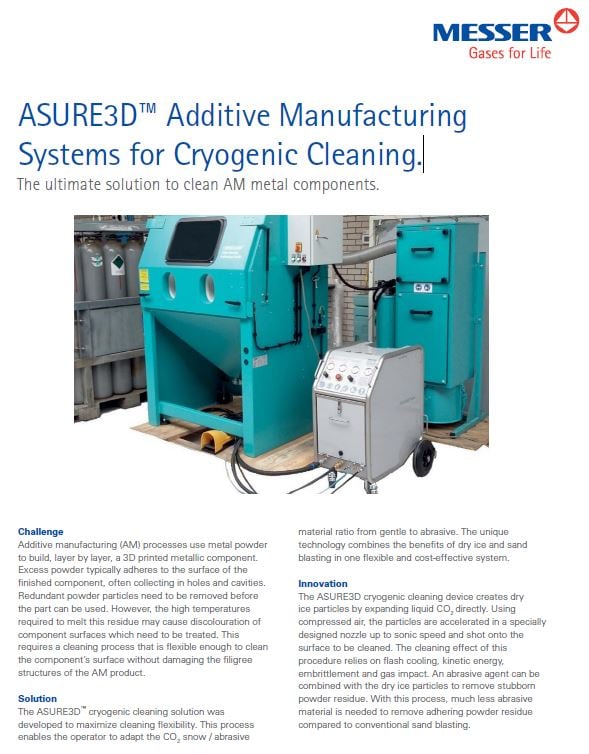

Additive manufacturing (AM) processes use metal powder to build a 3D printed metallic component. Excess powder typically adheres to the surface of the finished component, often collecting in holes and cavities. Redundant powder particles need to be removed before the part can be used. The ASURE3D™ cryogenic cleaning solution was developed to maximize cleaning flexibility.

The ASURE3D™ Powder Cabinet, providing atmosphere control for powder metal storage quality, was designed specifically to retain and protect the quality of valuable, sensitive additive manufacturing (AM) metal powders from the adverse effects of ambient air and humidity.

Flameless oxy fuel combustion in preheating of various vessels is an efficient method of cutting heating times, improving fuel economy, reducing greenhouse gas emissions and extending vessel refractory lining life. The OXIPYR system now makes this energy efficient preheating application available for use in smaller vessels and runners such as foundries and micro steel mills.

The Messer high pressure liquid pump is a modern, cost and energy-efficient unit that delivers nitrogen at high pressure. It doesn‘t degrade the gas purity when liquid nitrogen is gasified. If you're looking for high-pressure nitrogen or argon supply, look no further.

Many oxidation processes in refineries and petrochemical plants and in base chemical production use ambient air as an oxidant. Oxygen enrichment of these processes can increase plant capacity. Yield and selectivity can often be improved as well.

The CRYOASSIST system is a Messer cryogenic freezer used to rapidly crust-freeze food products prior to further processing or freezing. The Messer CRYOASSIST system is often used to “boost” mechanical freezing capacity and/ or aid in product handling processes, such as pressing, improve product yield and batter-breading.

Numerous oxidation processes in refineries, in petrochemical plants and in base chemical production use ambient air as an oxidant. Enriching the oxidation air requires careful measurement and control. Done successfully, it can increase the capacity of existing plants and make plant operation more flexible while reducing the amount of waste gas. Depending on the amount of process air, the Messer OXYBOOST™ Flow Control Skid and equipment meters oxygen into the process air until the desired concentration is reached.

Low temperature oxidation for NOx control.

The Messer nitrogen-methanol based atmosphere system generates a very flexible, high-quality atmosphere for carburizing, neutral hardening, annealing and sintering of steel. The nitrogen-methanol atmosphere system includes media storage and supply, flow control, distribution to the furnace, intake into the furnace and atmosphere control.

Messer ACS is an atmosphere control system designed for advanced atmosphere control during carburizing, neutral hardening and annealing in continuous furnaces. The system allows you to have control over the carbon potential in up to four zones per furnace as well as to optimize the heat treatment cycle. The functions of this system provide an indispensable tool in quality assurance work.

Messer‘s Modified Atmosphere Packaging brings you a full range of tailored solutions to meet the packaging requirements for meat and poultry.

Utilizing Modified Atmosphere Packaging (MAP) and the right gas mixture can extend the shelf life by at least a few days and possibly up to two weeks in raw packaged

fish such as cod, flounder, plaice, haddock, and whiting compared to packaging in traditional atmospheres similar to that of air.

The consumer is putting the dairy industry under ever-increasing pressure. On the one hand, they demand high-quality dairy foods with long shelf life; on the other, they

expect value for money. For food processors, the solution is an efficient production process that offers gentle handling and rapid processing.

Consumers demand high-quality fresh fruit and vegetables all year round. Careful handling supports hygiene and product integrity throughout the supply chain. For growers and food producers, the solution to meet these demands lies in highly sophisticated, efficient production and packaging processes that preserve taste, appearance, food safety, and value.

In stainless steel annealing, Messer’s atmosphere control system monitors the atmosphere in continuous and batch furnaces and controls the amounts of gases introduced into the furnace (hydrogen and nitrogen).

The powder metallurgy (PM) industry is challenged to increase the quality and consistency of sintered parts. Messer has developed a technology to control the sintering process and improve the mechanical strength of sintered parts.

At Messer, we believe that excimer lasers and related laser technologies help change the world. After working for decades in close collaboration with leading laser manufacturers, we have become the premier supplier of pure excimer laser gases, excimer laser gas mixtures and laser equipment.

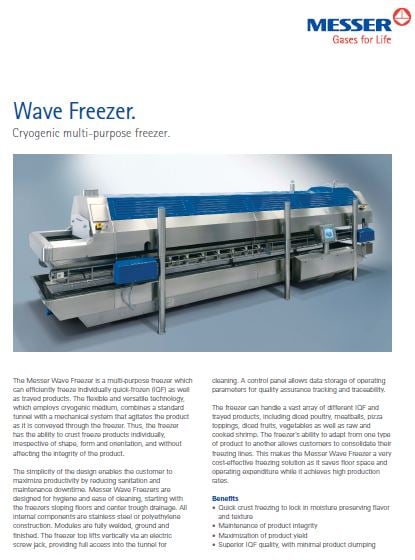

The Messer Wave Freezer is a multi-purpose freezer which can efficiently freeze individually quick-frozen (IQF) as well as trayed products. The flexible and versatile technology, which employs cryogenic medium, combines a standard tunnel with a mechanical system that agitates the product as it is conveyed through the freezer.

The Messer impingement freezer is designed to easily and quickly freeze a diversified range of product types. Smaller in size than conventional cryogenic freezers, it occupies less space on the production floor (typically 60% less floor space than conventional cryogenic tunnel freezers for the same production rate).

Companies relying on industrial gas for use in their manufacturing processes look for superior reliability, cost-competitive solutions, speed of response and experience from suppliers they know and trust. Messer offers a complete portfolio of on-site nitrogen and oxygen plants based on cryogenic or non-cryogenic technology.

The flameless Messer OXIPYR LEAF air-oxy fuel burner offers on-demand and adjustable productivity, superior temperature uniformity, cost savings and low NOx emissions.

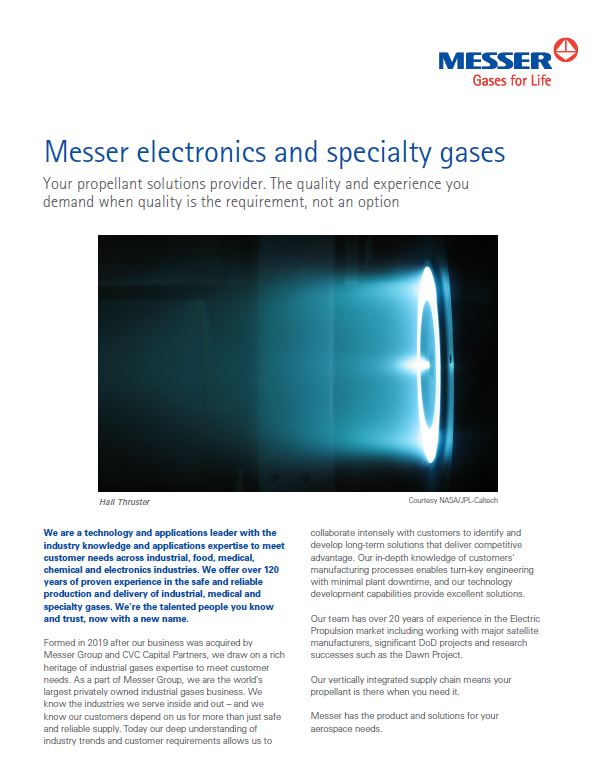

Messer electronics and specialty gases: Your propellant solutions provider. The quality and experience you demand when quality is the requirement, not an option.

Strategically injecting cryogens such as liquid nitrogen (N2) or carbon dioxide (CO2) directly into the bottom of a mixture chills food faster, more effectively and at a lower cost than other cooling methods. Bottom injection systems may deliver between 20 and 40 percent more chilling efficiency than alternate chilling approaches, as well as help processors improve production, appearance, and yield.

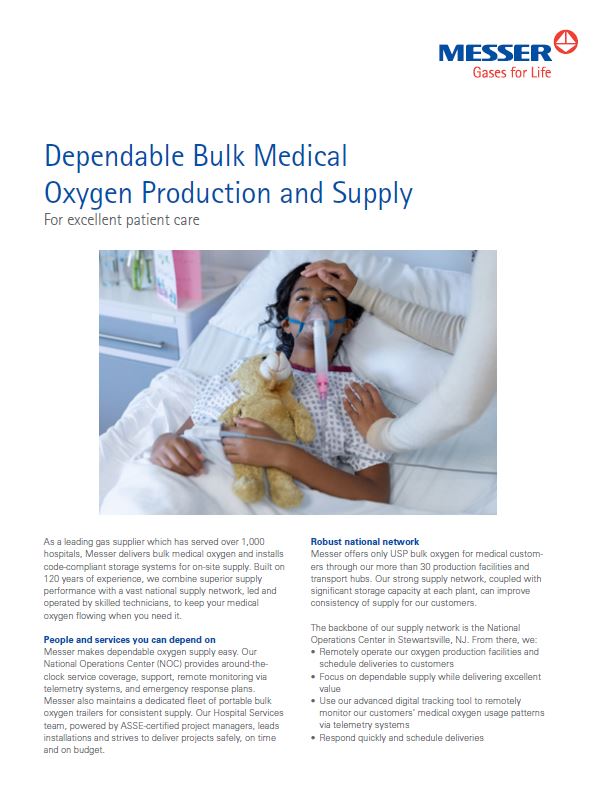

Built on more than 120 years of experience, Messer combines superior bulk oxygen supply performance with a vast national supply network. This is led and operated by skilled technicians, to keep your medical oxygen flowing when you need it.

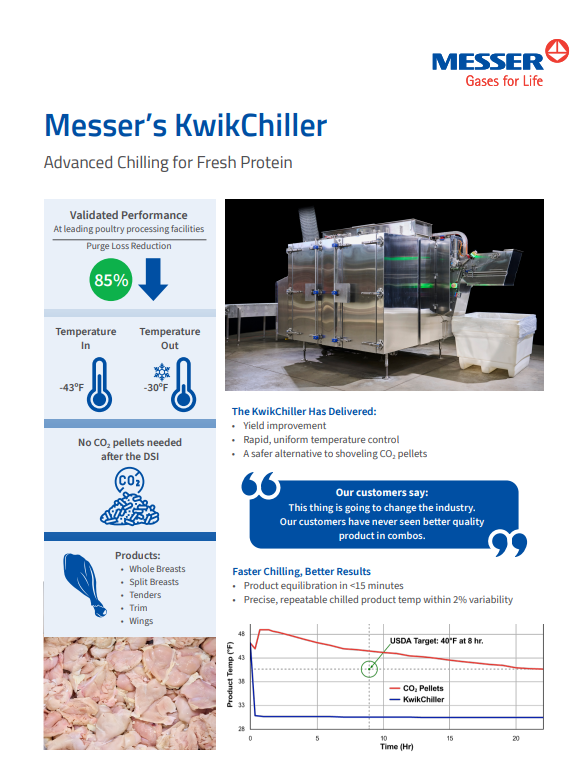

Developed in collaboration with food processors, the KwikChiller delivers the high production rates and product quality our customers expect. This game changing system can remove up to 30% more heat than traditional freezers in a compact footprint. It even fits through a standard dock door for easy installation.

The new KwikChiller delivers high-capacity chilling when floor space is at a premium. Developed in collaboration with poultry processors, successful installations demonstrated significant yield improvements and rapid, uniform temperature control. The nitrogen powered KwikChiller features an integrated exhaust, a safer alternative to shoveling CO2 pellets and fits through a standard dock door for easy installation.