Tyson Foods’ North Little Rock, Arkansas processing facility produces, among other items, individually quick-frozen (IQF), par-fried, and raw-breaded poultry products. Faced with production challenges, the company decided to convert its carbon dioxide (CO2) IQF line to a new liquid nitrogen (LIN)-based cryogenic technology. By upgrading to the new Messer Wave Impingement Freezer, Tyson Foods significantly increased production throughput while reducing the cost to freeze by, in some instances, up to 43 percent per pound while improving freezer reliability – all in a reduced footprint.

The challenge

The North Little Rock facility sought to increase production and reduce cost per pound on the IQF line. The plant manager, Wesley Simpson, who has been with the company for 28 years, knew from Tyson Foods’ plant metrics he “had the ability to run more capacity but [he] also wanted to keep freezing costs down.”

To maintain 4,500 pounds per hour (lb/hr) of capacity for raw poultry products, the facility was forced to restrict the belt loading on the former CO2 tunnel to make the transition into the mechanical freezer. “Managing the transition from the transfer belt to the mechanical freezer belt limited our ability to run more product. Additionally, CO2 snow was carrying over into the transfer belt which hindered production quality and drove up labor costs to spread and separate product. We actually stopped the CO2 freezer between shifts and cleaned out buildup inside the tunnel. The freezing capability wasn’t applicable to the product,” Simpson notes. To compound the problem, the CO2 tunnel could only reach -90 °F, making it incapable of adequately crust-freezing the product without reducing efficiency.

A new cryogenic technology

Messer's team evaluated the challenges posed by the CO2 freezer during an on-site consultation and were determined to find an optimum solution. The Messer team ran baseline product tests on the CO2 tunnel freezer by measuring production, cycle time, labor, IQF quality, and footprint to calculate freezing efficiency and the cost to freeze. After this diagnosis process, the Messer team recommended the new Wave Impingement Freezer, which is specifically designed for high-capacity freezing of IQF products. The North Little Rock facility would be among the first poultry processing plants in North America to incorporate this cutting-edge technology.

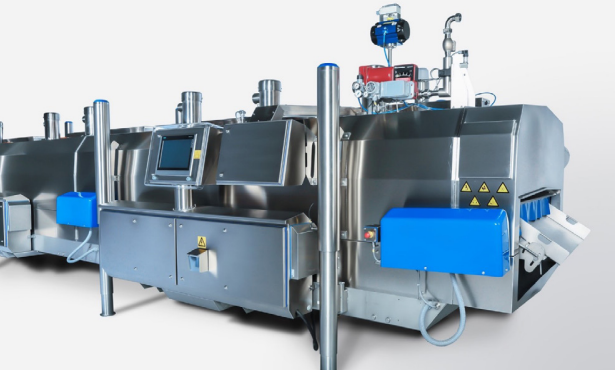

The patented high-capacity Wave Impingement Freezer combines the benefits of wave product agitation with impingement gas flows to achieve elevated levels of IQF productivity and quality in a small footprint. The wave-like motion agitates the product, maintaining product separation throughout the freezer. The high-velocity convective airflow increases heat transfer while reducing nitrogen consumption and overall cost-to-freeze. The hygienically designed Wave Impingement Freezer requires minimal maintenance, and its top lifts vertically for easy access to the tunnel for cleaning.

Measurable results

In the summer of 2021, Messer installed and commissioned the Wave Impingement Freezer, validated its operation, and established metrics for comparison with the CO2 tunnel freezer. Compared to the CO2 tunnel freezer, the Messer Wave Impingement Freezer significantly increased throughput while reducing the cost per pound of chilling. The wave action reduced product marriages and reduced product sticking or tearing on the belt, benefits which increased finished yields. It also reduced the required labor to spread and separate product, avoiding costly downtime during normal production hours.

“Historically, with a three-line operation, we operated 80 hours per week and produced roughly 1 million pounds per week (lb/week) or 52 million pounds per year (lb/year),” says Simpson. “Now, we’re processing six days per week, 20 hours per day, up from four days per week, and we increased production from 4,500 lb/hr average production to rates of 6,600 lb/hr, with peaks of up to 8,000 lb/hr. These production increases help give us the flexibility to respond to demand increases and tight labor markets.”

“We were hoping to run 1.5 million lb/week,” says Simpson, “but we’re actually averaging 1.7 million lb/ week. We’re on track to produce roughly 85 million lb/year — absolutely a record for the plant.”

“Being a small plant,” Simpson concludes, “we don’t always see the latest equipment and new technologies. I’m very thankful Messer gave us the opportunity to compete with larger facilities with state-of-the-art equipment.” The project’s success has brought a very positive focus on the North Little Rock facility.

After several months of operation, the Messer Wave Impingement Freezer has achieved increased production and improved equipment reliability at a lowered cost per pound. Furthermore, the new freezer improved not only IQF quality but also workplace spirit.

“Our people aren’t coping with the previous freezer, so frustration levels are down, and morale is up,” Simpson observes. “It is literally a win for everyone. It’s been a game changer for North Little Rock.”