Ask our team. We're ready to help!

Whether you need additional oxygen capacity to support your activated sludge process, contain odors or prevent septic conditions in your wastewater transfer pipes, Messer may have the BIOX solution for your individual wastewater treatment challenge.

If your business depends on industrial gases, you need a dependable supplier of quality products. You also need a leader in industrial gas technologies, committed to delivering solutions that create value in areas of productivity, quality and reduced operating costs that allow you to maintain focus on your core business. This is where Messer excels, and these pillars form the cornerstone of our success.

Welcome to the epicenter of innovation and customer solutions in applied gas technologies - the Messer Technical Center in Cleveland, Ohio. Here, our team of Messer engineers demonstrate leading application technologies to customers and innovate to address emerging industry needs.

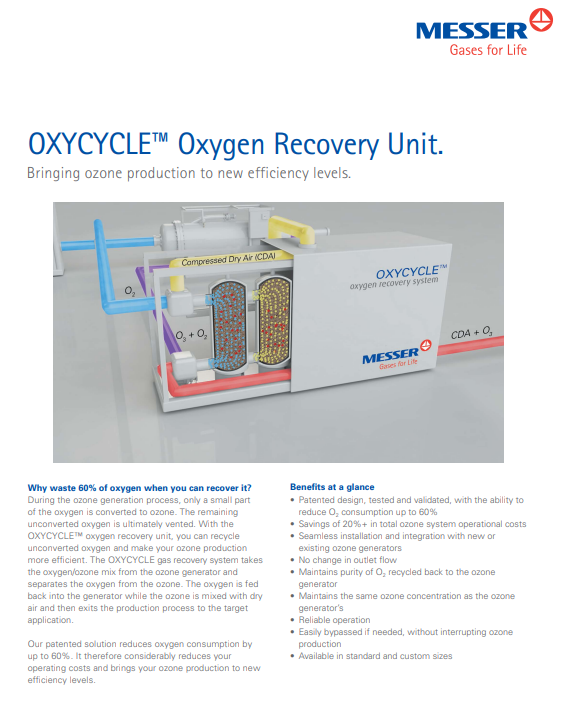

Messer's patented OXYCYLE oxygen recovery unit reduces oxygen consumption by up to 60%, reducing operating costs and bringing ozone production to new efficiency levels.

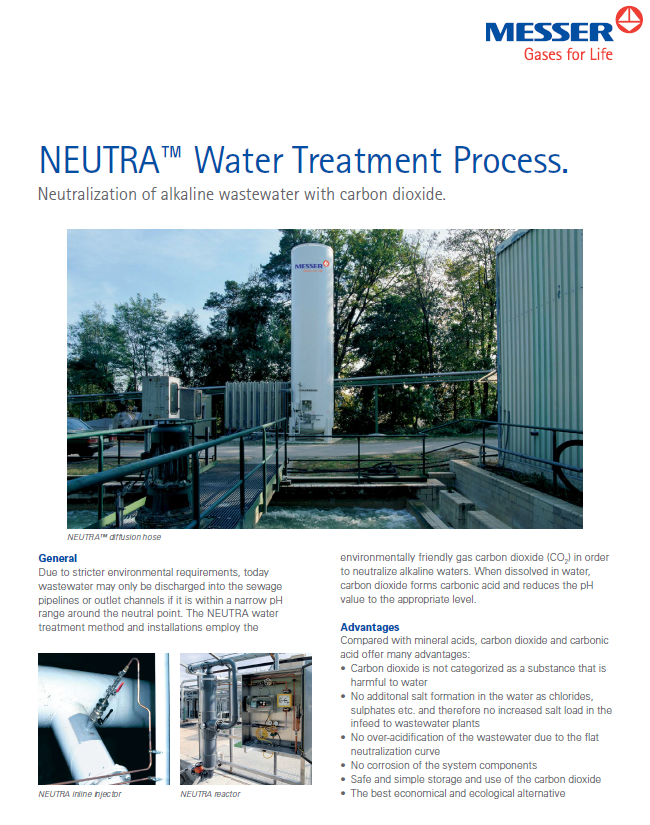

The NEUTRA water treatment method and installations employ carbon dioxide in order to neutralize alkaline waters. When dissolved in water, carbon dioxide forms carbonic acid and reduces the pH value to the appropriate level.

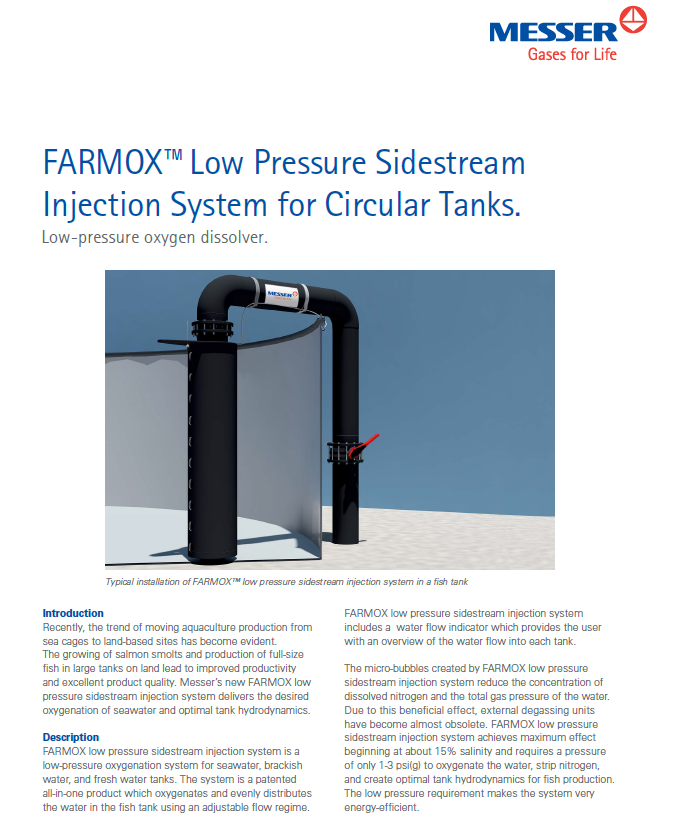

The FARMOX low pressure sidestream injection system is a low-pressure oxygenation system for seawater, brackish water, and fresh water tanks. The system is a patented all-in-one product which oxygenates and evenly distributes the water in the fish tank using an adjustable flow regime.

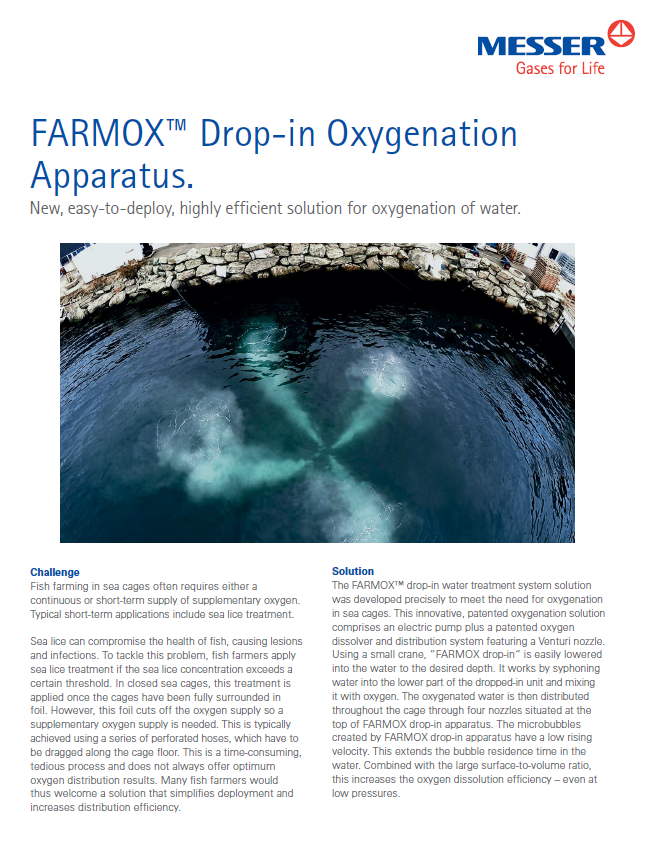

The FARMOX™ drop-in water treatment system solution was developed to meet the need for oxygenation in sea cages.

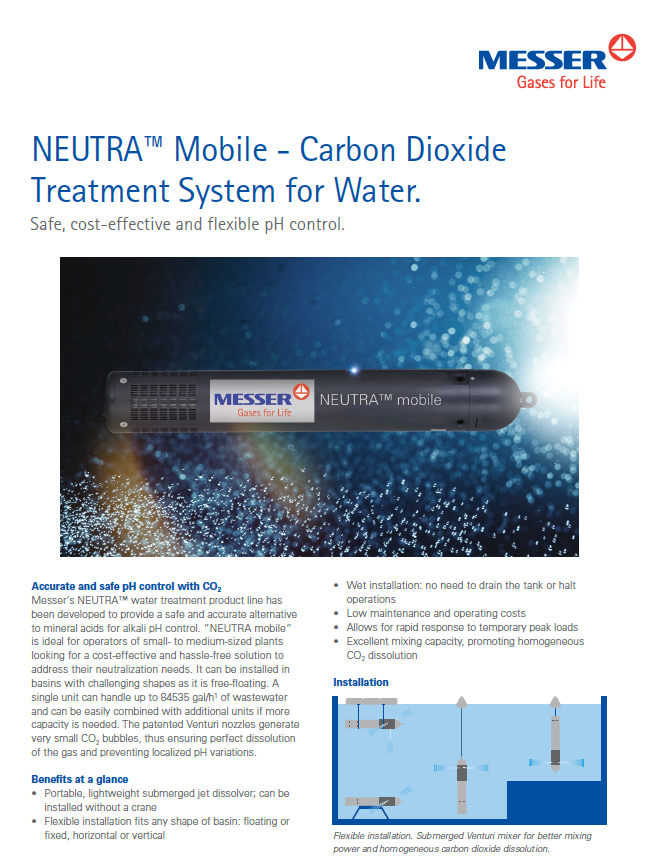

Messer‘s NEUTRA™ water treatment product line has been developed to provide a safe and accurate alternative to mineral acids for alkali pH control. “NEUTRA mobile“ is ideal for operators of small- to medium-sized plants looking for a cost-effective and hassle-free solution to address their neutralization needs.

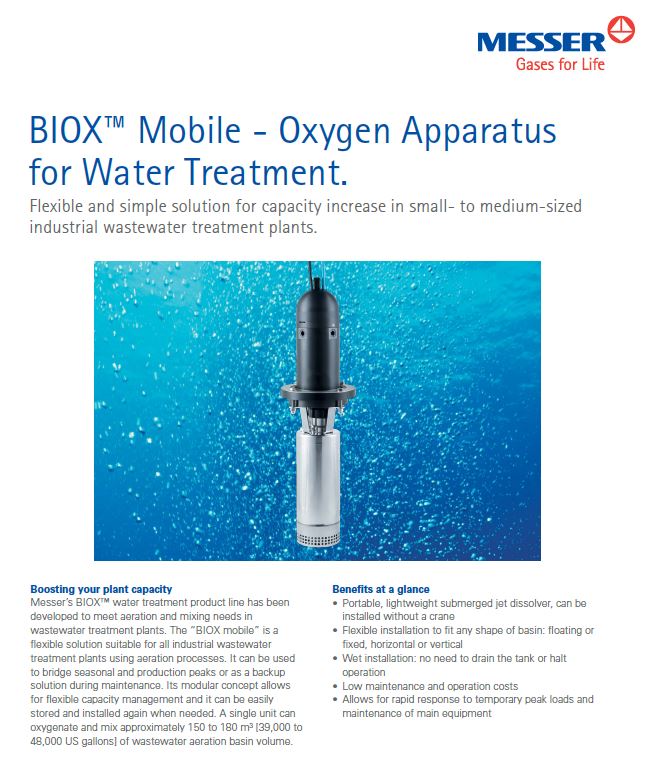

Messer’s BIOX™ water treatment product line has been developed to meet aeration and mixing needs in wastewater treatment plants. The “BIOX mobile” is a flexible solution suitable for all industrial wastewater treatment plants using aeration processes.

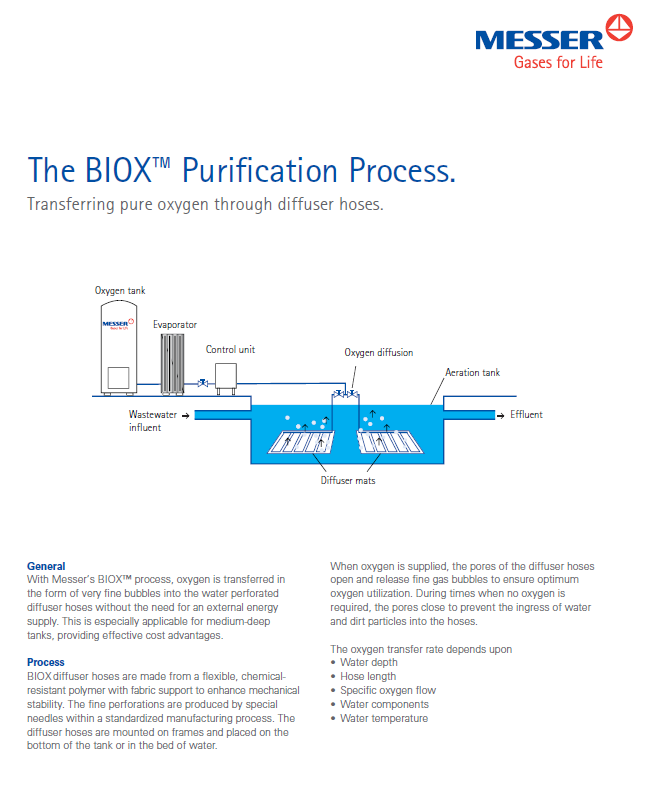

With Messer‘s BIOX™ process, oxygen is transferred in the form of very fine bubbles into the water perforated diffuser hoses without the need for an external energy supply. This is especially applicable for medium-deep tanks, providing effective cost advantages.