Contact us. We're ready to help!

Aluminum Extrusion Die Cooling Process

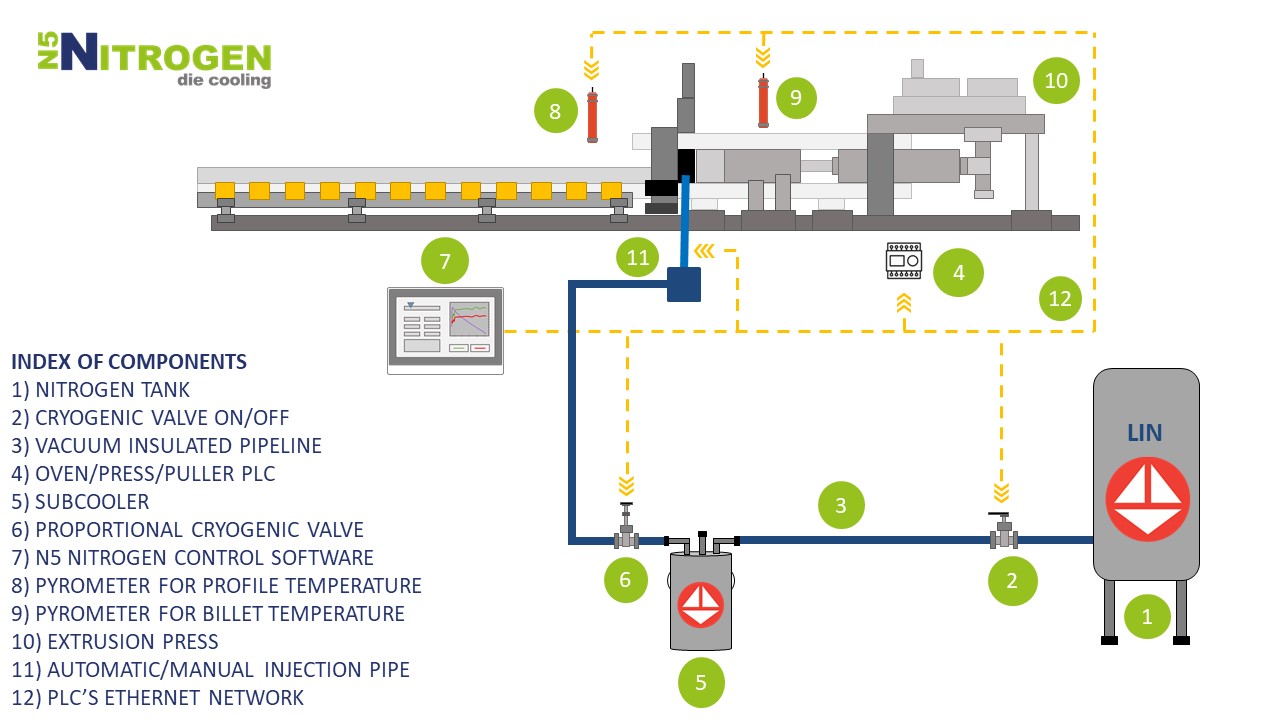

Messer can offer a sophisticated solution to deliver liquid nitrogen to the bearing zone. Both the layout of cooling channels in the die and the conditioning of the nitrogen with a subcooler are essential to this process. With control of the flow, as shown in this image, the active cooling enhances the capacity of the press and the quality of the surface. This can result in increased productivity and profit for your aluminum extrusion operation.