Contact us. We're ready to help!

Oxy fuel combustion refers to a process that combusts fuels like natural gas using pure oxygen. Traditional combustion uses air which is made up of about 21% oxygen, 79% nitrogen and small concentrations of many other gases. Nitrogen does not contribute to the combustion. Instead, it absorbs a large portion of the heat generated from combustion, leaving less heat available for the process. Reducing the presence of nitrogen in the furnace and using oxy fuel burners delivers more available heat for higher throughput, thereby improving efficiency, leaving fewer products of combustion and a reduced carbon footprint. The radiation of heat transferred to the metal from the oxy fuel flames is much higher compared to air fuel, allowing for faster heating of the metal without elevating the furnace temperature.

Metal production is one of the most energy-intensive industries on Earth, requiring temperatures usually reserved for the inside of an active volcano. As any melt shop manager can testify, the monetary cost of generating and maintaining such awe-inspiring temperature can be staggering. Oxy fuel burners are commonly used by aluminum, iron, steel, copper, brass and lead producers to improve efficiency for their high-temperature furnaces. Oxy fuel can be found in:

Other applications for oxy fuel include glass production, fossil fuel power generation, and carbon dioxide (CO2) capture and sequestration initiatives.

Though it seems counter intuitive, oxy fuel can increase production while lowering emissions. Since there is less nitrogen in the combustion mix, the heat generated from oxy fuel combustion contributes to melting more metal, rather than un-used heat being lost through the furnace exhaust. As a result, less fuel is consumed which reduces CO2 emissions from the furnace. Due to the oxygen rich fuel mixture, the oxy fuel flue gas is reduced to primarily CO2 and water with little or no nitrogen. Thus, inherent nitrogen oxide (NOX) formation can be avoided. Though some NOX can form due to air ingress from furnace leaks, proper burner location and leak management can achieve very low NOX emissions.

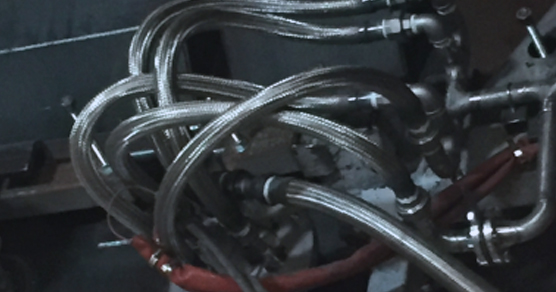

Messer OXIPYR low emission burners are a proven oxy fuel solution. Available in a full range of customizable configurations, they can create a more homogenized furnace temperature which can result in:

For example, a recently installed OXIPYR system reduced cycle times for reheating 4-3/4” billets in a rotary hearth furnace by half and reduced overall energy consumption by a full 63%.

OXIPYR LEAF oxy fuel burners provide enhanced control, giving operators the ability to dynamically switch from air to pure oxygen, or any mix in between. This flexibility allows furnaces to increase productivity using oxygen when needed, while conserving oxygen supply at times when cycle time is not a factor or fuel costs drop. OXIPYR LEAF burners help you balance production demands with profitability.

Messer offers installation, commissioning, repair and maintenance services for the OXIPYR gas burner systems for industrial use; and combustion solutions for related markets. To learn more about OXIPYR burners, please download the data sheets below.

"Flameless" oxy fuel burners to raise productivity and lower costs and emissions.

Flexibility to switch from straight air-fuel to oxy fuel with lower NOx emissions.

When Bermco Aluminum approached Messer to help improve their furnace production capacity, our team came up with a low capital solution that increased melt rates and extended refractory life.