Xenon plays a mission-critical role in modern spacecraft propulsion. As the preferred propellant for Hall-effect and ion thrusters, it enables efficient, long-duration maneuvering for satellites and deep-space missions, supporting everything from station-keeping to orbital transfer.

Xenon, due to its limited global production and stringent aerospace purity requirements, requires careful planning. For procurement teams and propulsion engineers, choosing the right gas supplier is a strategic decision with direct implications for success.

This guide outlines considerations when looking for a xenon gas supplier, including critical considerations for the quality, logistics, and technical standards that matter for aerospace applications.

The Role of Xenon in Ion Propulsion

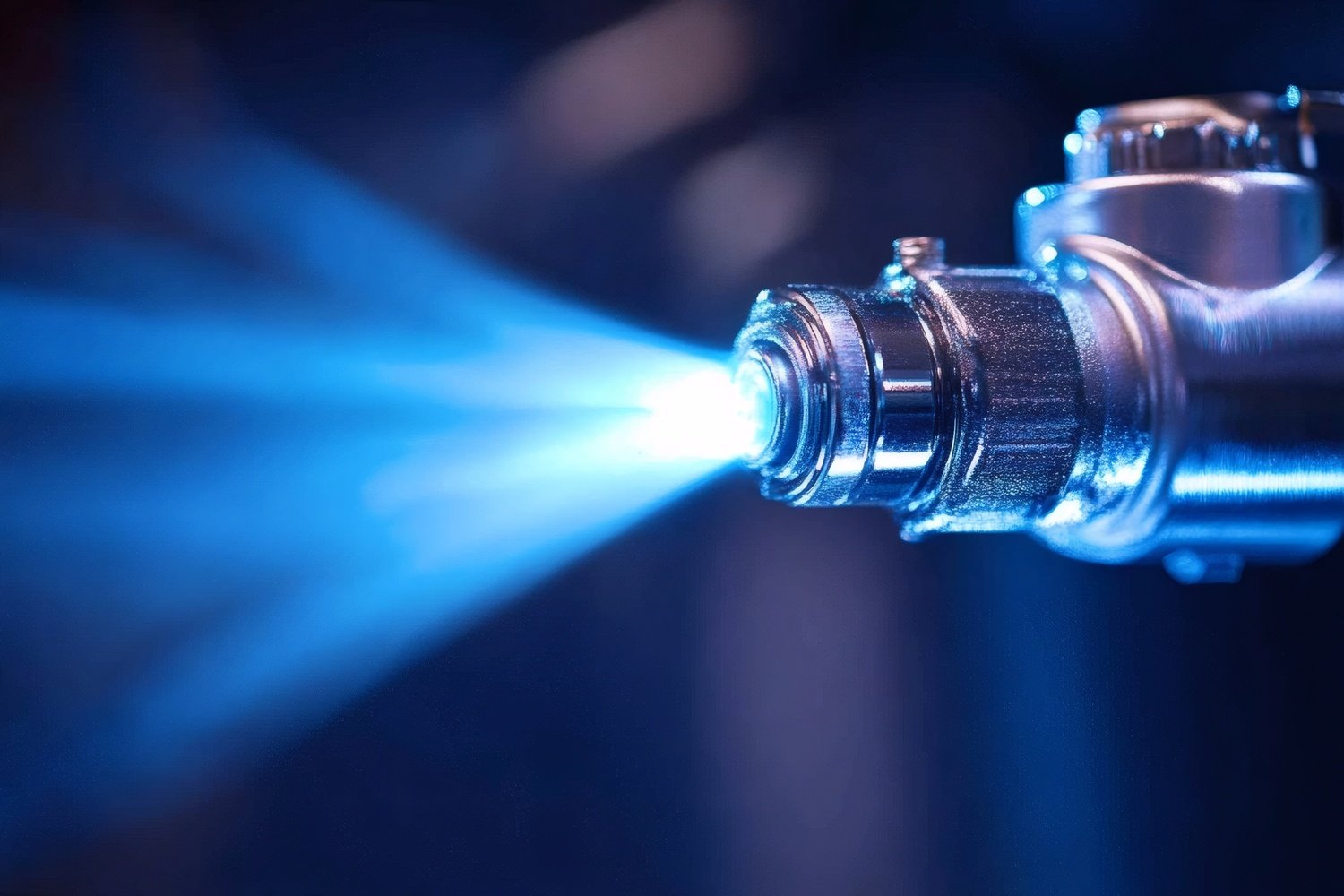

Unlike chemical thrusters, which produce large amounts of thrust for short bursts, ion and Hall-effect thrusters generate small amounts of continuous thrust over long periods. This thrust allows spacecraft to maneuver efficiently using only minimal amounts of propellant in the vacuum of space, an essential advantage for satellite station-keeping, deep-space missions, and long-duration orbital adjustments.

Xenon is the propellant of choice for most electric propulsion systems. Its high atomic mass and low ionization energy make it ideal for forming dense, stable plasma with relatively low power requirements. Its chemical inertness also minimizes corrosion and contamination risk inside the propulsion system, reducing wear on sensitive components over time.

Compared to alternatives like krypton or argon, xenon delivers superior performance per unit of mass, which allows satellites to conserve fuel, save space, and operate longer. In a system where every gram counts and every subsystem must perform flawlessly for years, xenon’s physical properties make it exceptionally well suited to the demands of modern spacecraft design.

That performance, however, depends on gas purity. Trace contaminants like moisture, hydrocarbons, and oxygen can erode or foul thruster components, destabilize plasma discharge, or degrade performance over time. A contaminated xenon fill can potentially reduce the lifespan of a propulsion system by years or introduce mission-critical risks that are impossible to correct once in orbit.

Xenon Supply Chain Challenges

The xenon market is small, specialized, and highly sensitive to demand cycles. Annual global production is limited, and supply can tighten quickly during surges in satellite manufacturing or government launch activity. Because of costs and availability, xenon is usually secured well in advance, often under long-term contracts. Lead times can stretch for months, and buyers who wait until late in the integration process may face delays or shortages.

In this context, strategic sourcing and advance planning are essential. Suppliers should offer transparent sourcing, rapid delivery capabilities, and the flexibility to align with mission-specific delivery windows.

What to Look for in a Xenon Gas Supplier

Xenon procurement for ion propulsion demands exacting standards. Aerospace buyers need suppliers who can meet ultra-high purity requirements, maintain tight process controls, and deliver reliably on mission timelines. The criteria below reflect important technical, operational, and logistical benchmarks that matter when sourcing xenon for spacecraft propulsion.

1. Supply Chain Availability

Xenon is exceptionally scarce, and disruptions in global supply can result in long lead times, inflated pricing, or procurement failures. When mission schedules are fixed months or years in advance, delay in xenon delivery may impact launch timelines or force costly design compromises.

That’s why domestic sourcing is a critical risk management tool. A U.S.-based xenon supply chain can minimize exposure to geopolitical shocks, customs delays, or transoceanic freight disruptions, all while promoting faster fulfillment in urgent or high-stakes scenarios.

Questions to Ask:

- “Is your xenon produced and purified domestically?”

- “Do you maintain buffer stock for emergency or mission-critical needs?”

2. Ultra-High Purity Specifications

Ion propulsion systems are extremely sensitive to contaminants. Even trace amounts of moisture, hydrocarbons, or oxygen can disrupt plasma discharge, erode thruster components, or cause arcing within propulsion hardware.

That’s why aerospace applications typically demand xenon purity of 99.999% (5.0 grade) or higher. This level of purity helps ensure stable thrust, efficient ionization, and minimal fouling over long mission durations.

To meet this standard, the supplier must maintain tight control over every step of the purification and filling process. Look for clear documentation of impurity thresholds (especially for moisture, CO₂, O₂, and total hydrocarbons) and confirmation that those levels are achieved consistently across batches.

Questions to Ask:

- “What purity levels do you guarantee for aerospace-grade xenon?”

- “Can you provide detailed impurity specifications with each delivery?"

3. Contamination Control & Filling Standards

High-purity xenon can still be compromised during transfer, cylinder prep, or packaging. To protect gas integrity, suppliers must maintain strict handling procedures and verifiable quality protocols at every step. Look for suppliers that can offer:

- ISO 9001 certification for quality management systems

- ISO 14001 for environmental management practices.

These standards help ensure consistency, traceability, and accountability across production and delivery. Suppliers should also follow relevant CGA (Compressed Gas Association) guidelines for cylinder evacuation, leak testing, and safe gas handling. Cylinders must be thoroughly cleaned, vacuum-purged, and checked for residual moisture or contaminants before filling.

Questions to Ask:

- “Do you follow CGA standards for gas transfer and cylinder prep?”

- “How do you prevent contamination during filling and shipment?”

4. Batch Traceability and Documentation

Mission-critical programs demand full visibility into the supply chain, including batch-level traceability and documentation for every cylinder delivered. At minimum, a supplier should provide:

- Certificates of Analysis (CoAs) confirming actual measured impurity levels

- Certificates of Compliance (CoCs) affirming that gas meets stated specifications

- Documentation that ties each cylinder to a unique batch number and fill history

- SDS (Safety Data Sheets) that comply with customer documentation needs

Questions to Ask:

- “Can you provide CoAs and CoCs for each batch or cylinder?"

- “Is your traceability system auditable and tied to production data?”

5. Delivery Container Compatibility

High-pressure xenon delivery requires specialized packaging, especially for launch site or integration facility environments. Aerospace customers typically use DOT-rated steel or aluminum cylinders, manifolded packs, or clean-certified containers designed for small-volume, ultra-pure use.

Depending on the phase of your mission, you may require different solutions:

- High-pressure cylinders for propulsion system integration

- Manifold packs or loading carts for satellite fueling operations

- Custom-labeled or cleanroom-conditioned containers for launchpad delivery

- Xenon recovery experience where used or vented xenon is collected, can be purified and reused

Your supplier should be equipped to support all of the above and guide you on which formats best align with your system requirements.

Questions to Ask:

- “What types of xenon delivery containers do you offer for aerospace use?”

- “Can you support cleanroom packaging or certified cylinders for launch sites?”

Source Strategically for High-Stakes Performance

Xenon may only make up a tiny fraction of a spacecraft’s total mass, but its quality can determine whether a propulsion system performs flawlessly for years or fails prematurely in orbit. For aerospace teams operating on tight margins and tighter timelines, the stakes couldn’t be higher.

At Messer, we support aerospace customers not only with high-purity xenon but also with the technical collaboration and supply assurance their missions demand. Through our state-of-the-art specialty gas facility in Coolbaugh, Pennsylvania, we operate advanced blending stations in clean, controlled environments to avoid contamination and ensure consistency. Our facility is equipped with precision analyzers capable of verifying xenon mixtures down to parts per million.

Every cylinder is carefully prepared to remove residual moisture or contaminants before filling, and all mixtures are packaged in high-pressure cylinders, loading carts, or custom-certified containers tailored to the customer’s handling and transport requirements. We provide full Certificates of Analysis with each delivery and ensure that every fill is fully traceable to its production batch, analysis results, and transfer conditions.

Our team frequently collaborates with spacecraft manufacturers and propulsion engineers to develop and test custom xenon mixtures, often starting with small pilot batches to validate performance before scaling up. We also work directly with engineering teams to design support equipment, such as xenon loading carts, and ensure that everything meets aerospace standards for cleanliness, leak-tightness, and operational safety. When needed, we dispatch trained technicians to support equipment operation at integration facilities or launch sites and perform final quality control and leak testing before and after loading.

By offering both the technical capabilities and the responsive logistics required for urgent aerospace timelines, including same-day delivery from our domestic supply network, Messer acts as a true strategic partner in xenon sourcing, helping customers execute complex missions with confidence.

Comments

Messer makes no warranty of any kind with respect to the subject matter, the completeness, or accuracy of this blog. Messer is not responsible for any actions (or lack thereof) taken as a result of relying on or in any way using information contained in this blog. In no event shall Messer be liable for any damages resulting from reliance on or use of information in this blog. Readers should take advice from a qualified professional when dealing with specific situations. Descriptions of, or references or access to, other publications within this blog do not imply endorsement of those publications. This blog may contain technical inaccuracies and changes to the information may be made at any time.

Gas products are hazardous. The use or misuse of gas products involves serious risks, including injury, disability and death. Users of gas products must use the Safety Data Sheets for the gas products to warn their employees and others who are exposed to the gas products or hazards associated with such products.