Ask our team. We're ready to help!

If your business depends on industrial gases, you need a dependable supplier of quality products. You also need a leader in industrial gas technologies, committed to delivering solutions that create value in areas of productivity, quality and reduced operating costs that allow you to maintain focus on your core business. This is where Messer excels, and these pillars form the cornerstone of our success.

Welcome to the epicenter of innovation and customer solutions in applied gas technologies - the Messer Technical Center in Cleveland, Ohio. Here, our team of Messer engineers demonstrate leading application technologies to customers and innovate to address emerging industry needs.

At Messer, we believe that excimer lasers and related laser technologies help change the world. After working for decades in close collaboration with leading laser manufacturers, we have become the premier supplier of pure excimer laser gases, excimer laser gas mixtures and laser equipment.

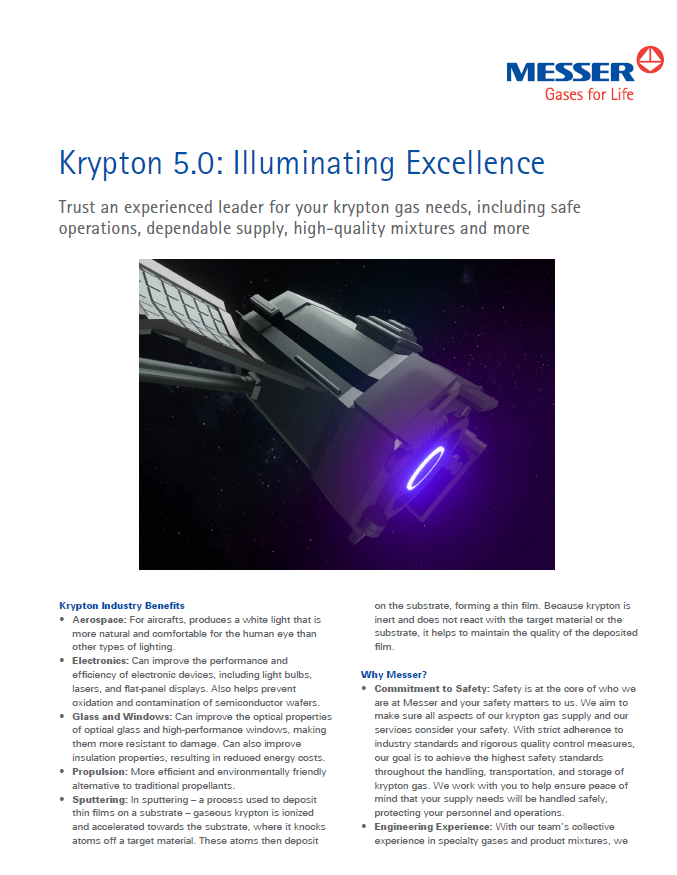

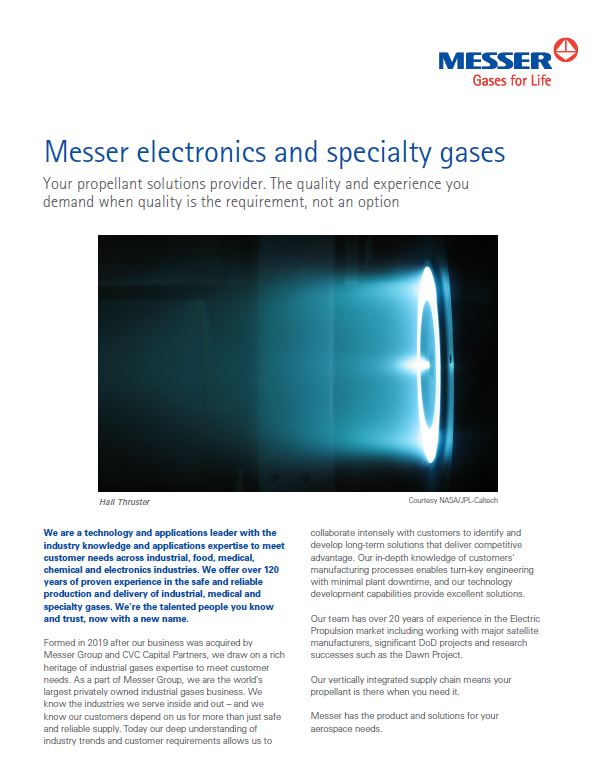

Messer electronics and specialty gases: Your propellant solutions provider. The quality and experience you demand when quality is the requirement, not an option.