Ask our team. We're ready to help!

From Messer's latest technology for enhancing well productivity through the power of combining gases and nanoparticles, to our best-in-class carbon dioxide and nitrogen service operations, we are your trusted provider.

This revolutionary new system updates the Huff-n-Puff concept with cutting-edge nanoparticle recovery technologies. The result is an ingeniously innovative, incredibly effective EOR solution that will give fresh life to your older wells.

Whether you need additional oxygen capacity to support your activated sludge process, contain odors or prevent septic conditions in your wastewater transfer pipes, Messer may have the BIOX solution for your individual wastewater treatment challenge.

If your business depends on industrial gases, you need a dependable supplier of quality products. You also need a leader in industrial gas technologies, committed to delivering solutions that create value in areas of productivity, quality and reduced operating costs that allow you to maintain focus on your core business. This is where Messer excels, and these pillars form the cornerstone of our success.

Welcome to the epicenter of innovation and customer solutions in applied gas technologies - the Messer Technical Center in Cleveland, Ohio. Here, our team of Messer engineers demonstrate leading application technologies to customers and innovate to address emerging industry needs.

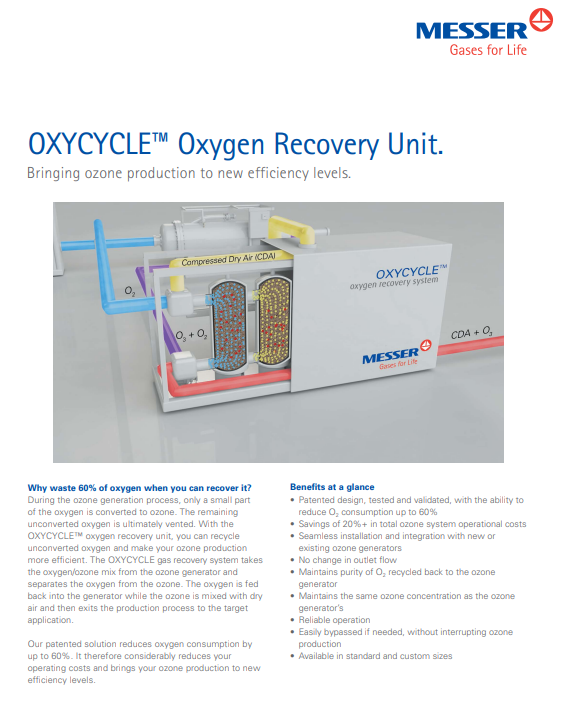

Messer's patented OXYCYLE oxygen recovery unit reduces oxygen consumption by up to 60%, reducing operating costs and bringing ozone production to new efficiency levels.

In order to comply with regulations, one customer was looking for an environmentally-friendly way of SWS gas treatment.

Oxygen enrichment for intensification of Claus processing.

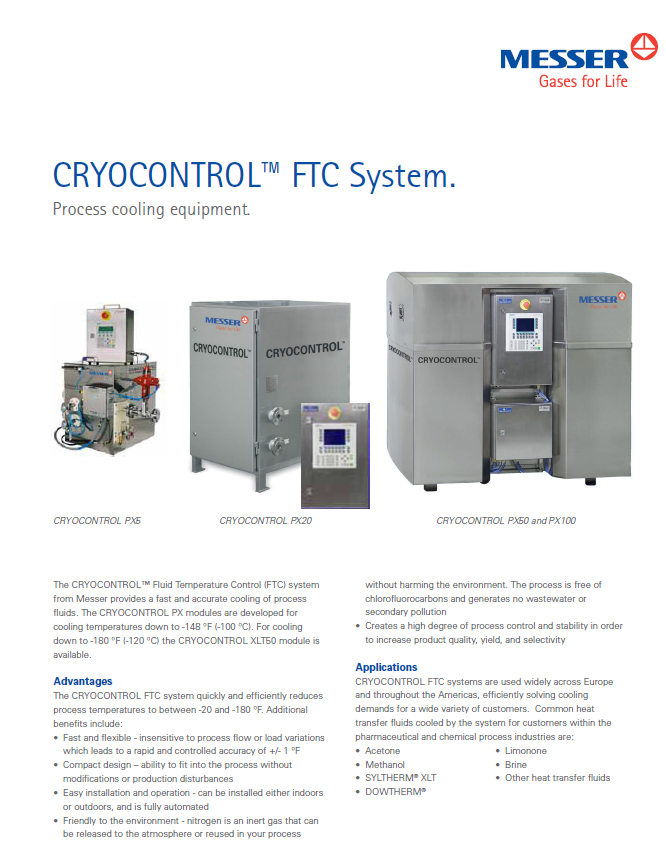

The CRYOCONTROL™ Fluid Temperature Control (FTC) system from Messer provides a fast and accurate cooling of process fluids.

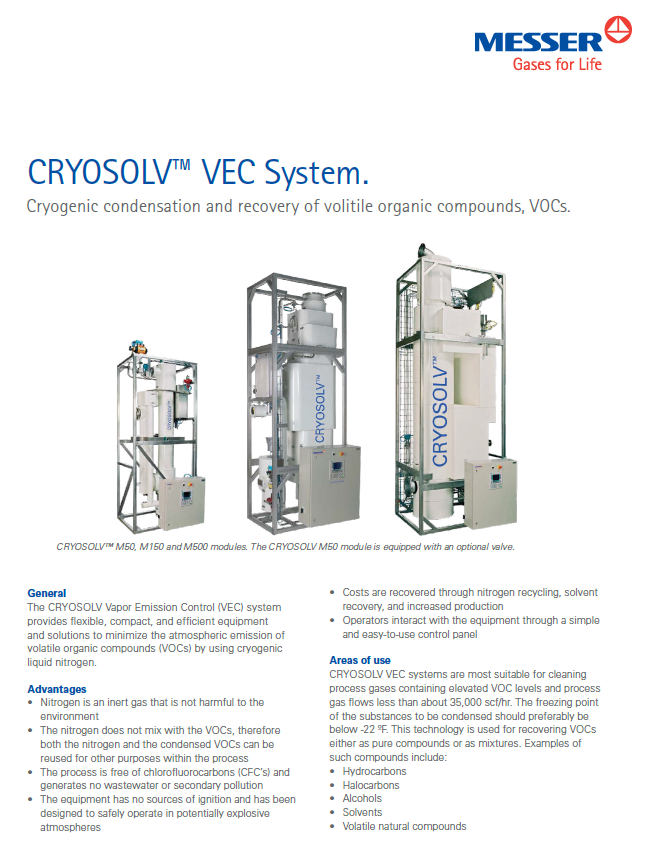

The CRYOSOLV Vapor Emission Control (VEC) system provides flexible, compact, and efficient equipment and solutions to minimize the atmospheric emission of volatile organic compounds (VOCs) by using cryogenic liquid nitrogen.

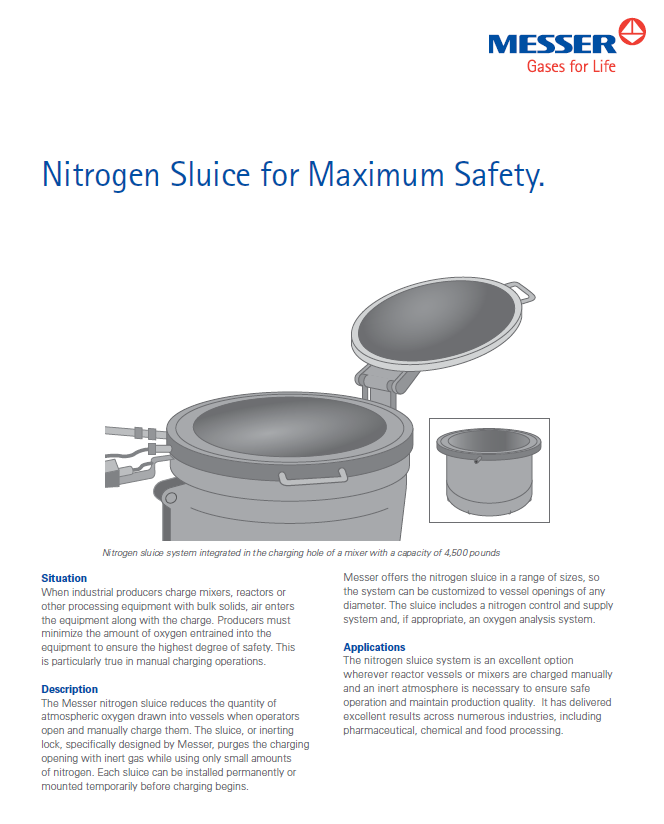

The Messer nitrogen sluice system is an excellent option wherever reactor vessels or mixers are charged manually and an inert atmosphere is necessary for safe operation and to maintain production quality. It has delivered excellent results across numerous industries, including pharmaceutical, chemical and food processing.

Many oxidation processes in refineries and petrochemical plants and in base chemical production use ambient air as an oxidant. Oxygen enrichment of these processes can increase plant capacity. Yield and selectivity can often be improved as well.

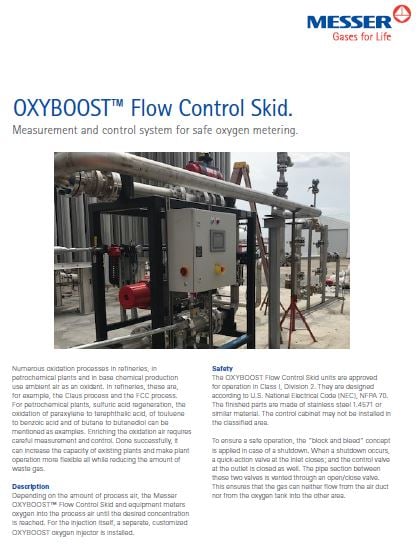

Numerous oxidation processes in refineries, in petrochemical plants and in base chemical production use ambient air as an oxidant. Enriching the oxidation air requires careful measurement and control. Done successfully, it can increase the capacity of existing plants and make plant operation more flexible while reducing the amount of waste gas. Depending on the amount of process air, the Messer OXYBOOST™ Flow Control Skid and equipment meters oxygen into the process air until the desired concentration is reached.

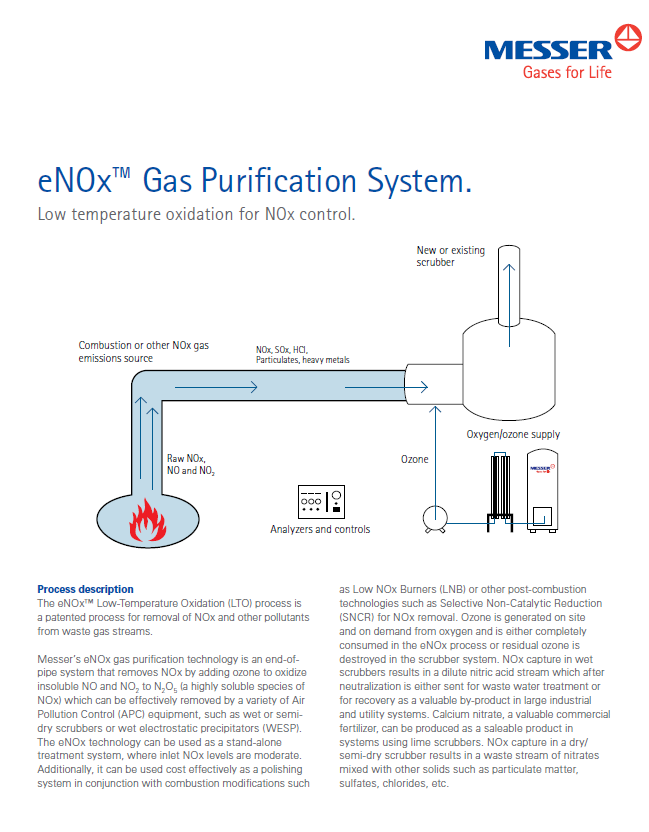

Low temperature oxidation for NOx control.

Messer's eNOx solution delivers high NOx removal capabilities, achieving efficiency rates in excess of 95%.

Maintaining oxygen levels above 90% is key to efficient fish farming. To prevent lower oxygen levels that threaten fish health, Messer's FARMOXTM family of oxygenation solutions is your answer.

Messer's suite of solutions can help you preserve the environment in efficient and effective ways.