Ask our team. We're ready to help!

Messer‘s ASURE3D™ atmosphere control uses state-of-theart engineering to continuously analyze the gas atmosphere in your powder chamber with high precision and without cross-sensitivity.

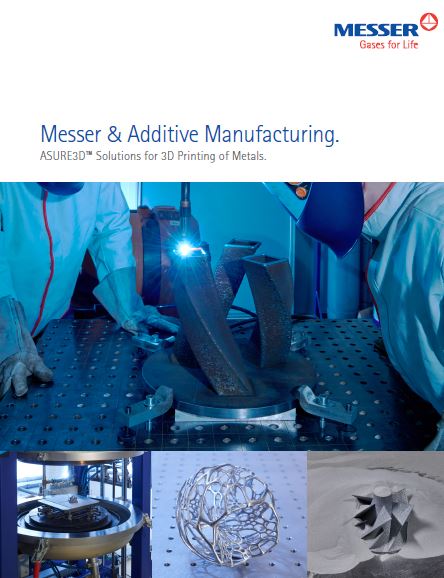

3D printing (also called additive manufacturing) of metals has only been developed in the last few years but is already seen as one of the technologies for the future. 3D printing involves the use of a variety of gases at different stages of the production chain. Messer ASURE3D™ equipment and system atmosphere control uses state-of-the art technology to continuously analyze the gas atmosphere in your build chamber with high precision and without cross-sensitivity.

If your business depends on industrial gases, you need a dependable supplier of quality products. You also need a leader in industrial gas technologies, committed to delivering solutions that create value in areas of productivity, quality and reduced operating costs that allow you to maintain focus on your core business. This is where Messer excels, and these pillars form the cornerstone of our success.

Welcome to the epicenter of innovation and customer solutions in applied gas technologies - the Messer Technical Center in Cleveland, Ohio. Here, our team of Messer engineers demonstrate leading application technologies to customers and innovate to address emerging industry needs.

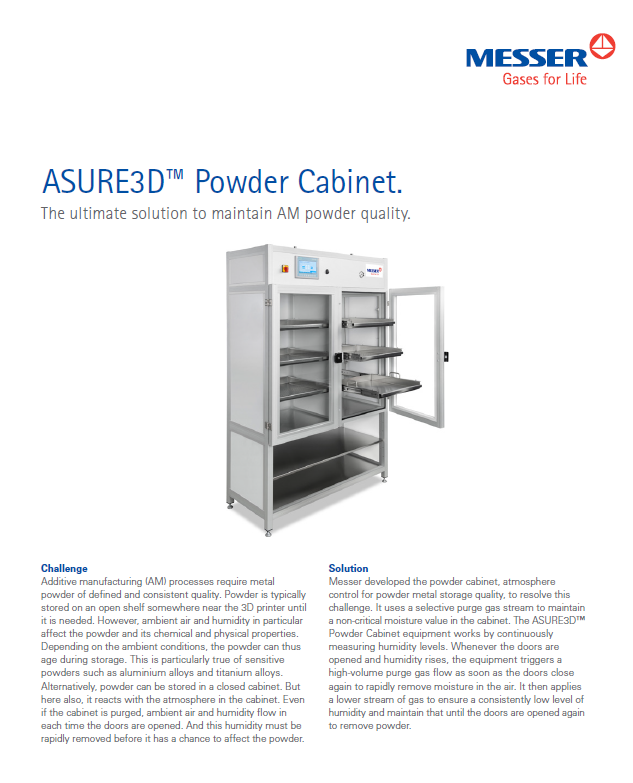

The ASURE3D Powder Cabinet equipment is valuable for cabinets with multiple storage shelves as these are a great place for ambient air and moisture to hide and constantly affect the powder particles. The equipment uses a highly directional gas stream and a carefully selected flow rate to reach the desired moisture value.

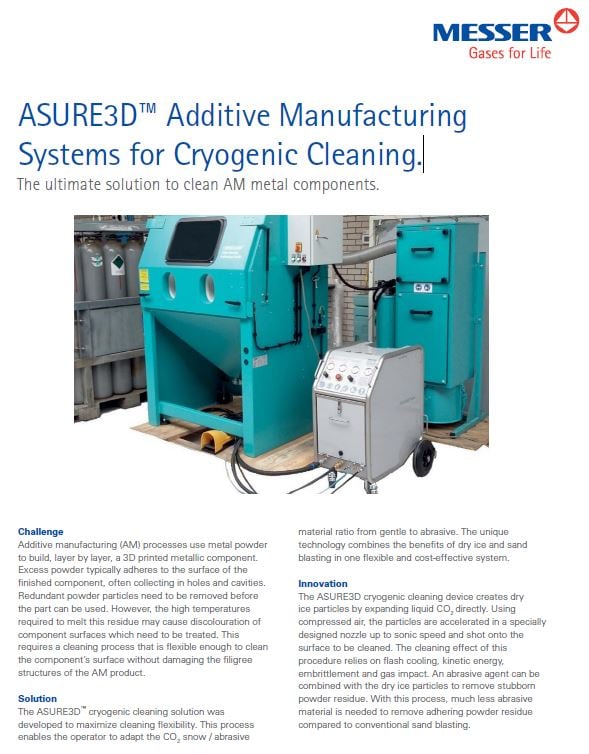

Additive manufacturing (AM) processes use metal powder to build a 3D printed metallic component. Excess powder typically adheres to the surface of the finished component, often collecting in holes and cavities. Redundant powder particles need to be removed before the part can be used. The ASURE3D™ cryogenic cleaning solution was developed to maximize cleaning flexibility.

The ASURE3D™ Powder Cabinet, providing atmosphere control for powder metal storage quality, was designed specifically to retain and protect the quality of valuable, sensitive additive manufacturing (AM) metal powders from the adverse effects of ambient air and humidity.