Lower heat treatment costs and lift productivity and product uniformity

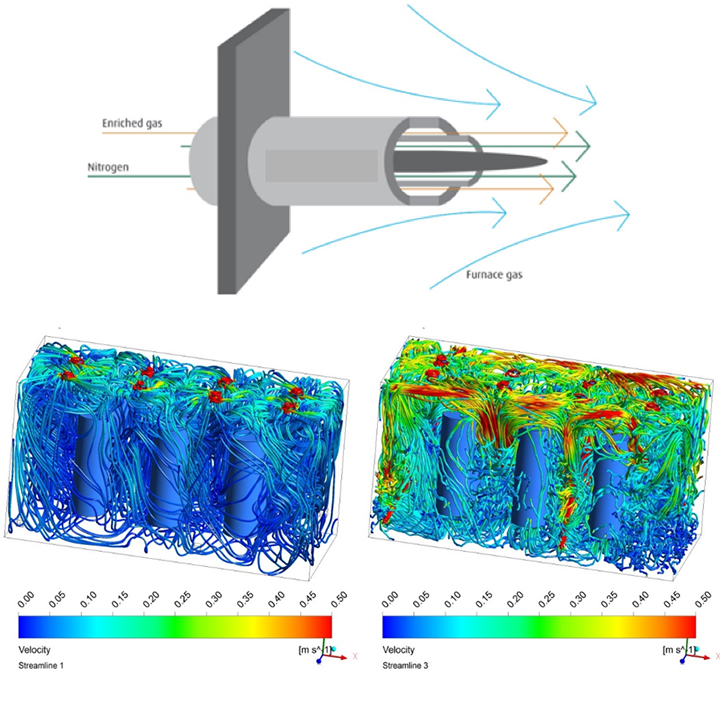

Whether your heat treatment process of choice is annealing, carburizing, carbonitriding, hardening, nitriding, or nitrocarburizing, furnace atmosphere circulation and uniformity is always a concern—unless you have HSGI high-speed gas injection technology from Messer.

Does a throughput boost of up to 20% sound good? How about greater product uniformity? Better gas convection, less soot, less oxidation, or improved carbon transfer and gas utilization? HSGI delivers all of these benefits without additional gas consumption in most cases. Plus, its heat-resistant HSGI nozzles operate without fans—which means no leaks, reduced maintenance downtime and less spent on electricity and cooling water.

Best of all, HSGI technology fits almost any furnace, suitable for many Heat Treatment processes and every HSGI Solution is custom designed and built for its specific use.