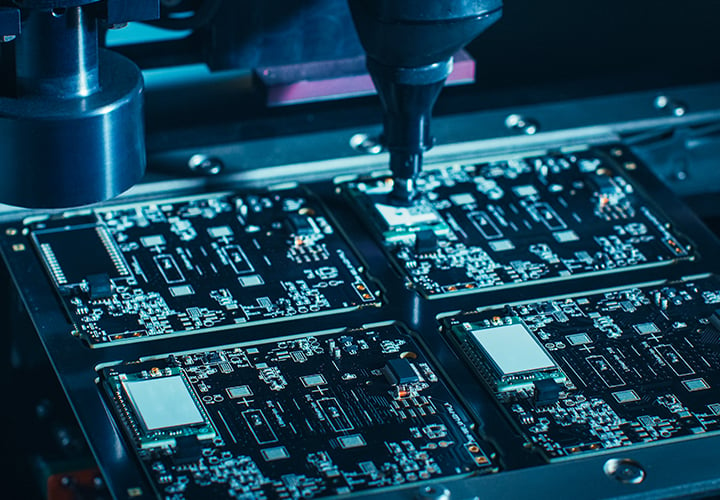

Printed circuit boards (PCBs) are everywhere around us, quietly nestled inside everything from TVs to toasters. If your business involves assembling those PCBs from piles of breadboards, resistors, and other components—and in particular soldering the resulting mosaic of components together—Messer is ready to help overclock your operation.

How? By installing Messer’s nitrogen-based soldering technology for inerting and atmosphere control. Our solutions create inert atmospheres that not only reduce connection defects from oxidation during soldering, but also curtail flux use, maintenance woes, and dross production during wave soldering. We can even widen your process window.

For instance, our local inerting system can easily convert an air wave soldering machine to nitrogen soldering, giving you cleaner prints, a 30% reduction in required maintenance, and 50-80% dross savings. Our atmosphere control system can reduce your gas costs by up to 40%.

Messer has the components and know-how to optimize any wave soldering or reflow soldering process. Whether you need to retrofit existing wave soldering machines, inert full-tunnel soldering systems, or simply secure a trusted source of bulk nitrogen, we have the solutions and expertise to meet your every need.

Messer local inerting system