Contact us. We're ready to help!

Plastic may be the single most versatile construction material in the history of the world, used for everything from soda bottles to surgical implants. Granted, the process of manufacturing (or demanufacturing) plastic products does present challenges—but Messer’s gases and technological solutions can help you optimize your production lines.

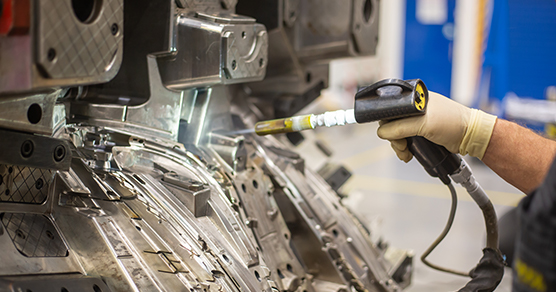

Newly formed plastic parts? You can rely upon Messer’s innovative cleaning systems to utilize “dry ice” CO2 snow to blast away any contaminants left over from the manufacturing or storage process, with no risk of abrasion or damage to the original part.

For more information on Messer’s gases and solutions for the plastics industry, click any of the links below or contact us.

Reduce cycle time and gas injector clogging by using nitrogen or CO2 by cooling parts from the inside. Messer offers an alternative to using water for cooling in complex molds.

For complex molds with hot spots, Messer replaces conventional water cooling with liquid CO2. Utilize the additional heat transfer from liquid CO2 to cool you molds uniformly and reduce cycle times and scrap parts.

Carbon dioxide (CO2) for cleaning, liquid nitrogen (LIN) for cryogenic grinding and separating, and more.